Factories are becoming smarter and more efficient in today’s world. One way they achieve this is with laser welding. Laser welding is a particularly special type of welding that makes use of lasers to join materials together. Such technology is the critical driver that enables factories to work faster and better. We know that constant improvement of production methods is important here at DMK. The addition of laser welding to our arsenal enables us to produce stronger, and better quality products. You can read about how laser welding increases production efficiency in smart factores and why you should choose it for manufacturing

All about the benefits of laser welding in Smart Factories for production efficiency

This is a game-changer for factories, laser welding. It does this by concentrating a powerful beam of light onto two pieces of metal, causing them to melt together. This method is very precise. This is because the welds are often neater with less waste. In fast-moving smart factories, laser welding can be a catalyst for making things go faster. Traditional welding, for instance, is time-consuming because workers need to prepare the metal and typically clean up afterward. Laser welding is quicker, and there’s less to clean up. This makes factories able to manufacture more items in shorter time

Another advantage of laser welding is its compatibility with a variety of materials. Whether it’s steel, aluminum or even plastic, laser welding is able to take care of it. This versatility also allows factories to use the same machines for multiple projects. This saves money and space. What’s more, laser welding machines can be automated, reducing the need for human labor to perform menial tasks. Streamlining the activation process minimizes the possibility for mistakes and enhances safety. And by having machines do the welding, there’s a lower risk of accidents than if humans performed the work

Additionally, the laser welding generates less heat compared to other welds. This is significant in that the surrounding heat sensitive materials are not heat damaged. In smart factories, where technology can be sensitive, it’s a huge upside. And allows for more elaborate designs with less risk of ruining parts. Ultimately, through laser welding, smart factories can operate more productively and effectively to deliver better products in a safe work environment

Why Add Laser Welding to the Manufacturing Mix

There are many benefits of incorporating laser welding in industrial processes. First, it enhances product quality. Laser welding is also known to be a lot more accurate, resulting in less loose or wobbly joints. Which is critical for industries like automotive and aerospace where safety is a primary concern. Customers trust that the pieces were crafted with care I mean, when you know each part is made with love and attention to detail, it builds trust among your customers. We strive for the best in quality, and laser welding allows us to reach it

Another benefit is cost savings. The upfront cost to set up laser welding might be higher, but it can ultimately save you money. Less error means less wasted material. And faster production can mean more staff churning out more products to sell. That can mean higher profits for manufacturers

Laser welding permits more creative designs, too. Because it can fuse together different materials with little heat, engineers could make new kinds of products. This allows for more creative design solutions. Factories can try out different shapes and materials that weren’t an option with traditional welding methods

And, lastly, employing laser welding is more environmentally friendly in factories. It’s better for the environment because there is less waste and energy used. Smart factories are already centered on being green, and laser welding is a perfect fit. At DMK, we know that it's not just about being efficient – it is also about being responsible

In short, adopting laser welding in your manufacturing process works. It increases productivity, leads to higher quality, reduces costs, fuels innovation and ensures sustainability. As factories advance, technologies such as laser welding will be a big part of that reshaping

Smart Laser Welding Techniques to Increase Production Efficiency

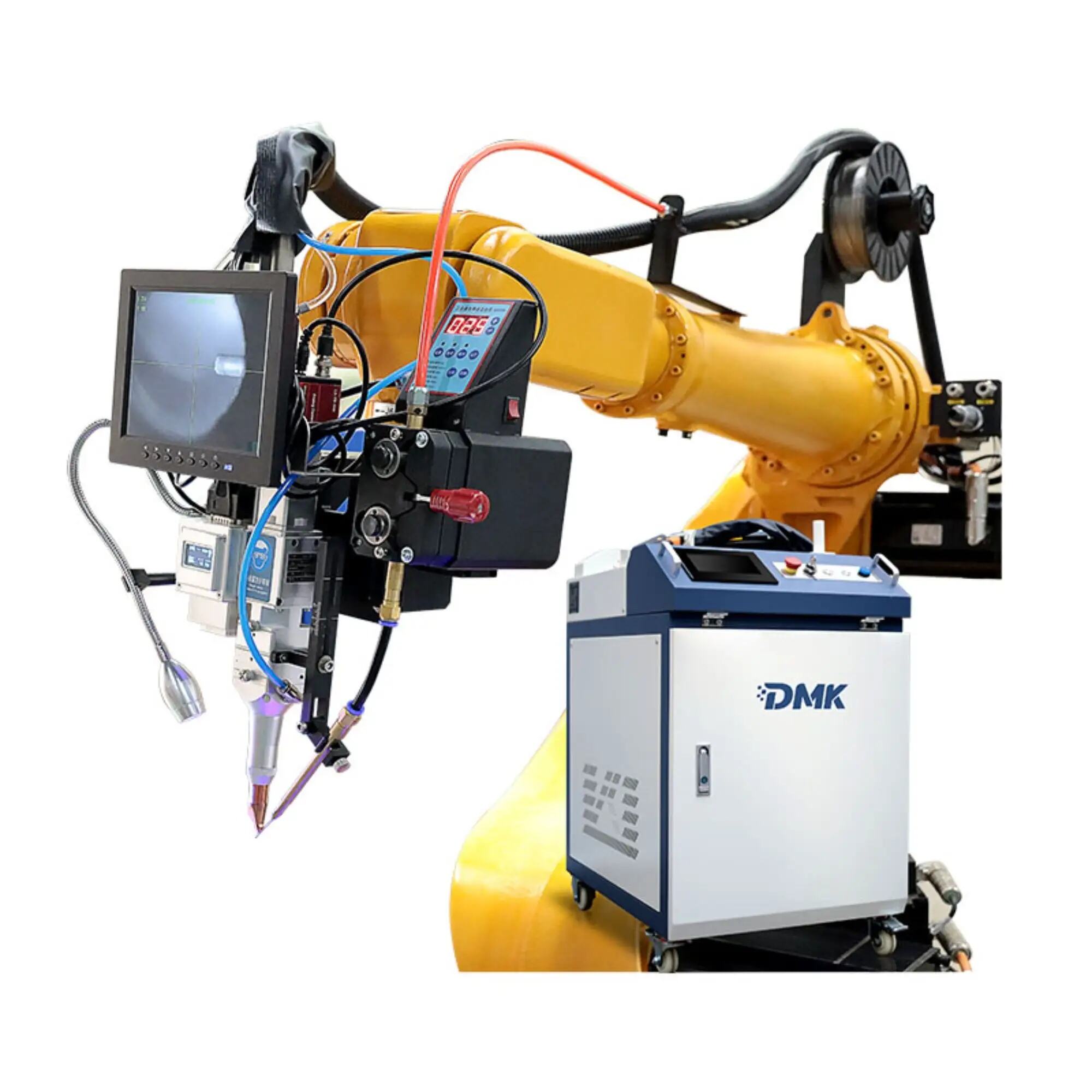

In the world of today, factories want to run faster and better. One of the best ways to accomplish that is through smart laser welding. We think new technology can save businesses time and money here at DMK. Uh, well first of all let us learn what laser welding is. It works by beaming a very strong light, created using something called a laser, in between two pieces of metal. This is a fast and accurate technique. In order to produce efficiently, factories must employ machines that are advanced enough to be operated automatically. These machines can be set to produce a weld with minimal intervention from workers. That means workers can attend to other important jobs while the machines keep working

A further way to increase efficiency is by integrating smart sensors, for example into laser welding systems. These sensors can verify if the weld is made properly. Any problems, the machine can fix it straight away. This avoids errors that might otherwise slow production. Another is to rely on software that monitors the welding process. This software can demonstrate how long each weld takes, and Manager can see where inefficiencies could be eliminated. Also important to note is that the need for workers to know how to operate such smart machines. When workers are well-trained in how to run the machines, they can troubleshoot to keep things on the rails. DMK also puts stress on the necessity of repairing and maintaining laser welding equipments. Keeping the machines in good condition can help avoid breakdowns that put a delay on product. That’s how, when smart machines are combined with sensors and tracking software alongside well-trained workers, factories can be just about as efficient as they will ever become with laser welding

Why Next Generation Production Prefers Laser Welding

Laser welding is getting more and more popular in the factories of this present day, and that isn’t without reason. A key factor is the sheer speed of it. Laser welding is capable to weld metals much faster than the conventional processes of welding. That means products can be produced quickly, which makes customers happy. At DMK, we understand that speed is the lifeblood of businesses that must satisfy increasing consumer demand in markets. A second reason why laser welding is desirable, is precision. The welding capacity may produce a small, strong weld in the workpieces. this one is essential to reassure that products are with high quality. Through well-made products, they break less often (less merchandise returned due to being broken) and their customers are happier

In addition, the amount of heat generated by laser welding is less than that of other methods. This is good as it minimizes the risk of these materials warping or being tarnished during welding. And it also means using less energy, which is good for the environment and your pocketbook. “A bonus of laser welding is being able to process multiple materials. From steel to aluminum to other metals, laser welding can do it. This flexibility can be key for factories that produce a range of products. The automation in laser welding also helps to minimize the labor costs. Less labor is required for the welding itself, as machines can do a significant portion of the work. The next thing for manufacturingFactories are in a relentless search for the next means to raise production, and laser welding is such a smart choice

Which Laser Welding System Is Best for Your Wholesale Business

The decision to select the best laser welding systems should therefore be taken with a clear mind by any wholesaler. At DMK, we know there are a lot of choices and it can be overwhelming. The first thing businesses should consider is the types of materials they will be welding. Some metals fare better with certain laser systems. So for instance, if your company primarily deals in steel, find a laser cutting system that’s been proven to be effective with steel. Next, take the materials into account. There are different systems for welding very thin materials and thicker ones. Being aware of the thickness of metals, which are intended to be working on is a plus for selecting an appropriate machine

Another factor to consider is the velocity of the laser welding system. A more efficient system can allow a company to produce more products, faster. But at the same time, we also have to balance speed and quality. A machine that is too fast could make weak welds. So, companies must search for solutions that can offer an unique balance of speed and high. Budget is another key consideration. The price of laser welding system can range, therefore it’s important to ensure that your choice meets both a business’s budget and production demand. Last but not least, what’s being offered in the way of support and training from the manufacturer is also very significant. A company like DMK not only provides training but also offers ongoing support after installation to ensure customers can maximize the capabilities of their laser welding systems. Wholesale businesses can select the best laser welding system to make them profitable by considering materials, thickness, speed, budget and support

Table of Contents

- All about the benefits of laser welding in Smart Factories for production efficiency

- Why Add Laser Welding to the Manufacturing Mix

- Smart Laser Welding Techniques to Increase Production Efficiency

- Why Next Generation Production Prefers Laser Welding

- Which Laser Welding System Is Best for Your Wholesale Business

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR