لقد حظي التصنيع الإضافي (AM) للسيراميك باهتمام كبير في السنوات الأخيرة نظرًا لاستخدامه العالي للمواد ودورته الإنتاجية القصيرة ودقة التشكيل الممتازة وقدرته على إنتاج أجزاء سيراميكية معقدة بكميات صغيرة. هذا يجعله جذابًا بشكل خاص...

اتصل بنا

التصنيع الإضافي للسيراميك (AM) قد اكتسبت اهتمامًا كبيرًا في السنوات الأخيرة بسبب كفاءة استخدام المواد العالية، والدورات الإنتاجية القصيرة، والدقة الممتازة في التشكيل، وقدرة على إنتاج أجزاء خزفية معقدة بكميات منخفضة. مما يجعلها جذابة بشكل خاص للإنتاج المخصص. ومع ذلك، وعلى الرغم من مزاياها، تواجه طباعة الخزف بإضافة المواد عائقًا رئيسيًا في طريق التصنيع: تكون العيوب مثل التشققات والمسام , التي تؤثر بشكل كبير على سلامة البنية والأداء الميكانيكي للأجزاء الخزفية.

من بين مختلف العيوب، التشقق تُعتبر هذه المشكلة من أهمّ المشاكل التي تُعيق التطبيق العملي للتصنيع الإضافي للسيراميك. يُمكن أن تُؤدي الشقوق إلى إضعاف مُكونات السيراميك بشكل كبير، وغالبًا ما تنشأ عن الإجهادات المُتبقية والسلوكيات الحرارية المُعقّدة المُلازمة لعملية التصنيع الإضافي.

يمكن تقسيم تقنيات الطباعة الإضافية للخزف بشكل عام إلى طريقة غير مباشرة و مباشر ، وذلك حسب ما إذا كانت هناك حاجة إلى معالجة لاحقة أم لا.

الطباعة الإضافية للخزف غير المباشرة عادةً ما يتضمن تشكيل بوليمر مملوء بالسيراميك يليه إزالة المادة الرابطة والتحميص ، حيث تتكون معظم الشقوق خلال هذه المرحلة.

التصنيع الإضافي السيراميكي المباشر ، من ناحية أخرى، يستخدم أشعة ليزر ذات طاقة عالية أو أشعة إلكترونية لصهر المساحيق السيراميكية بشكل انتقائي وتصلبها. مما يؤدي إلى تدرجات حرارية شديدة ومعدلات تبريد التدرجات الحرارية ومعدلات التبريد ، ويؤدي ذلك إلى إنتاج إجهادات حرارية وانكماشية وبقايا تُسبب أنواعاً مختلفة من الشقوق.

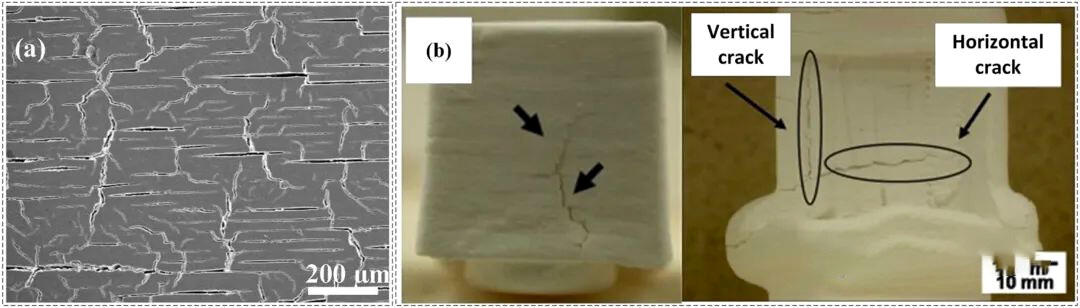

في التصنيع الإضافي غير المباشر للسيراميك، يتم عادةً تصنيف الشقوق حسب المرحلة التي تتشكل فيها:

شقوق التشكيل تحدث أثناء تشكيل الجسم الأخضر، وغالبًا بسبب تجاوز إجهادات الانكماش لقوة المادة الرابطة. تميل هذه الشقوق إلى أن تكون صغيرة، وتظهر على شكل شقوق دقيقة أفقية أو على شكل صليب تتراوح أبعادها من النانو إلى الميكرو.

شقوق التلبيد تظهر أثناء المعالجة عند درجات الحرارة العالية. هذه الشقوق أوسع، وموجهة بشكل عشوائي، وقد تكون عرضية أو طولية أو قطرية، وتؤثر بشكل كبير على الخصائص الميكانيكية.

يشمل التصنيف الإضافي:

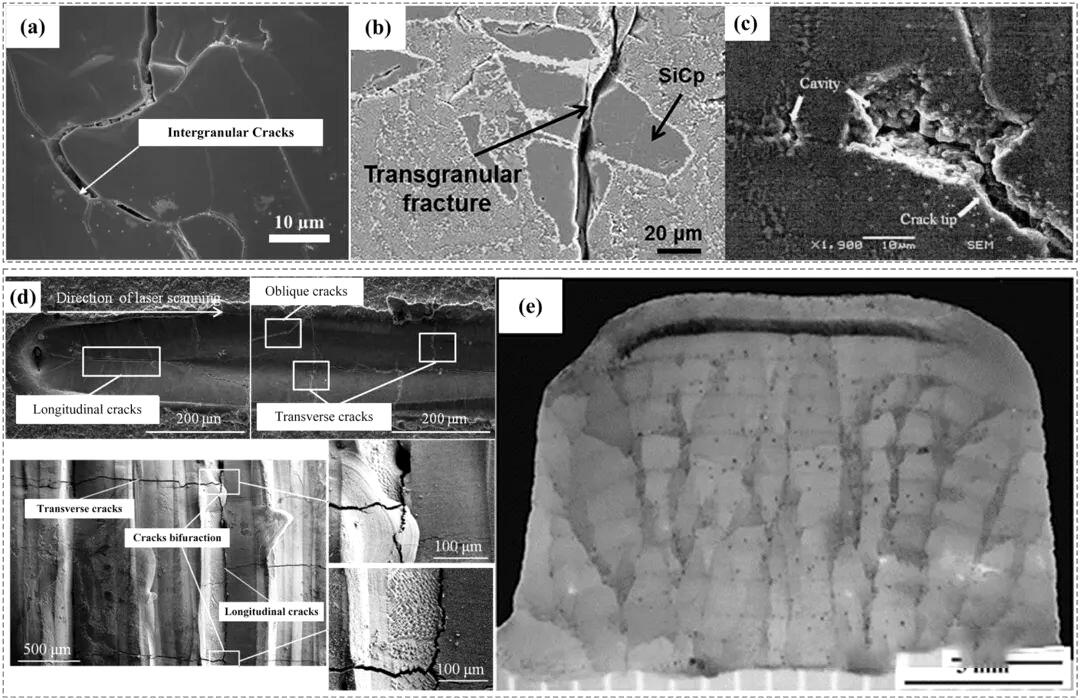

الشقوق الدقيقة ، وتقع عادةً على طول حدود الحبيبات أو حول المسام. قد تظهر هذه الشقوق كشقوق بين الحبيبات أو عبر الحبيبات، ويمكن أن تُظهر تفرعات أو انحرافات اعتمادًا على امتصاص الطاقة أثناء انتشارها.

الشقوق الكبيرة ، وهي أكثر وضوحًا وعادةً ما تنتشر على طول المناطق الضعيفة داخل المادة، وغالبًا ما تبدأ من مواقع المسام بسبب تركيز الإجهاد.

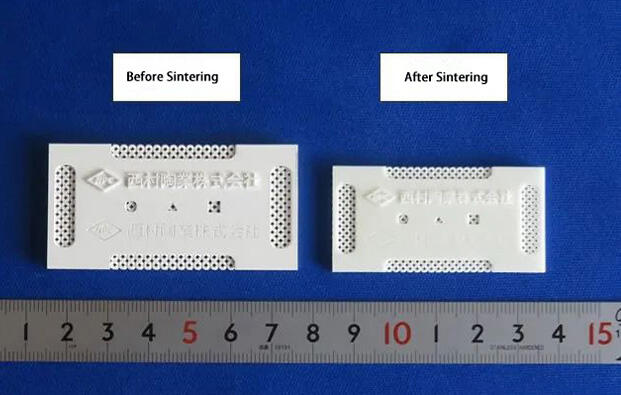

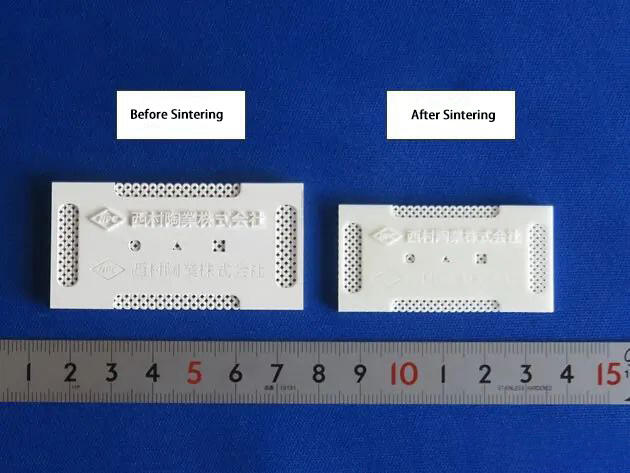

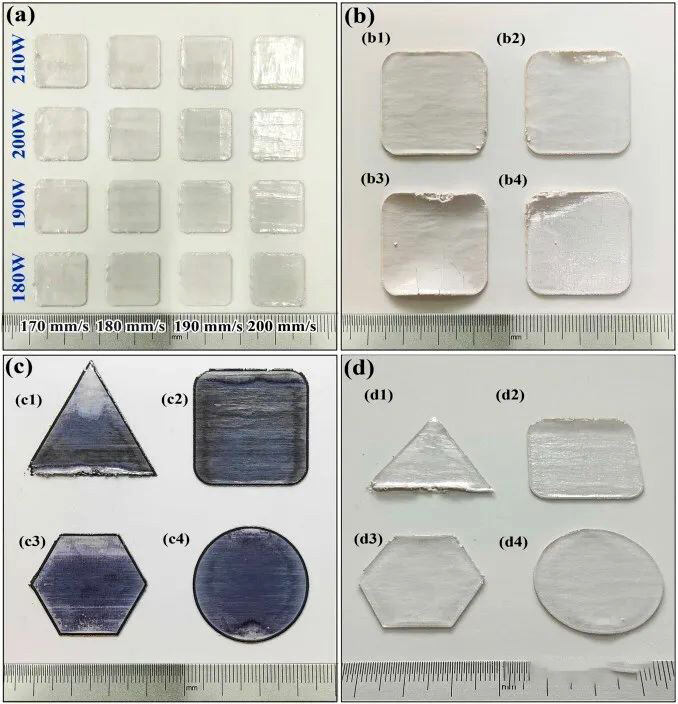

الشقوق في التصنيع الإضافي السيراميكي غير المباشر: (أ) تشكيل الشقوق؛ (ب) شقوق التلبيد.

مقارنة بين التصنيع الإضافي السيراميكي غير المباشر قبل التلبيد وبعده

في التصنيع الإضافي السيراميكي المباشر ، وعادةً ما تتطور الشقوق الكبيرة في اتجاهين:

الشقوق العرضية ، عمودية على اتجاه مسح الليزر.

الشقوق الطولية ، موازية لاتجاه المسح.

غالبًا ما تبدأ هذه الشقوق عند interface بين الطبقات المترسبة والمسحوق غير المذاب، وتتمدد نحو الداخل وأحيانًا تشكل أنماطًا قطرية. في الأنظمة التي تُغذى بالمسحوق، تظهر الشقوق عادةً في مركز طبقة الكلادينج أو على الجوانب. المنطقة المركزية تُظهر غالبًا شقوقًا طولية قصيرة وكثيفة، بينما قد تحتوي المناطق الحافة على شقوق أعمق وأكثر عزلة.

الشقوق في التصنيع الإضافي السيراميكي المباشر: (a-c) تشققات دقيقة؛ (d-e) تشققات كبرى

على الرغم من أن التطورات الأخيرة وسعت من إمكانيات تقنية السيراميك الإضافية (AM)، إلا أن إنتاج مكونات كبيرة الحجم وخالية من التشققات يظل تحديًا. ومن أبرز الصعوبات التي تواجه ذلك ما يلي:

تعتمد النماذج الحالية في الغالب على أسس تجريبية ومبنية على حدود الإجهاد المتبقية، مما يوفر رؤى محدودة عبر مواد وتقنيات مختلفة. يجب أن تأخذ المعايير الشاملة لتكون التشققات بعين الاعتبار طاقة حدود الحبيبات والربط الذري وطاقة سطح المسام - وهي مهمة معقدة في الأنظمة متعددة المكونات.

من الصعب التقاط التطور المكاني والزماني للتشققات تجريبيًا. إن استخدام تقنيات المحاكاة متعددة المقاييس المتقدمة المحاكاة متعددة المقاييس (مثل اللدونة البلورية باستخدام عنصر محدود، وطرق المجال الطوري) ضروري للتنبؤ بدقة ببدء التشققات ونموها تحت ظروف متعددة الفيزياء.

إن التدرجات الحرارية الشديدة هي خاصية متأصلة في التصنيع الإضافي المباشر، مما يجعل من الصعب تجنب تشكّل الشقوق. على الرغم من استخدام طرق مثل التسخين المسبق و المساعدة بالموجات فوق الصوتية لقد تم استخدامها للتخفيف من التوتر، لكن فعاليتها محدودة. إن تقنية الترسيب بمساعدة مجالات طاقة متعددة ، التي تجمع بين تحكم درجة الحرارة والضغط والاهتزاز، تُظهر إمكانات واعدة في كبح تشكيل الشقوق في القطع الخزفية الكبيرة.

دمج تقنيات المراقبة في الوقت الفعلي (على سبيل المثال لا الحصر، Tomographie بالأشعة السينية، والتصوير الحراري تحت الأحمر) مع الذكاء الاصطناعي وتعلم الآلة يمكن أن يحدث ثورة في اكتشاف العيوب ومنعها. من خلال تحليل البيانات أثناء العملية ودمجها في نماذج تنبؤية وأنظمة إعادة التغذية، يمكن تحسين المعلمات العملية ديناميكيًا لكبح تشكيل الشقوق قبل أن تتفاقم.

إن التصنيع الإضافي للخزف يمثل طريقًا مُحوِّلًا لإنتاج السيراميك المتقدم، ومع ذلك فإن تشكّل الشقوق تظل العائق الرئيسي إلى تطبيقاتها الصناعية. وعلى الرغم من أن الخصائص الشكلية للتشققات قد تم تسجيلها بشكل جيد، فإن آليات تشكّلها تختلف اختلافاً كبيراً بين الطرق غير المباشرة والطرق المباشرة.

فهم أصل التشققات وانتشارها وكيفية كبحها سيكون المفتاح لاستغلال الإمكانات الكاملة لتقنيات التصنيع الإضافة للسيراميك. إن الأبحاث الجارية التي تجمع بين علم المواد وهندسة العمليات والرصد الذكي تُعد ضرورية بشكل كبير للتغلب على هذا الحاجز ودفع تقنيات التصنيع الإضافة للسيراميك نحو الاستخدام الصناعي الرئيسي.