DMK manufactures custom laser welders that are used in high accuracy welding requirements across various industries. The laser-driven process in these devices provides a very accurate and fast way to make each pad, and quickly binds the fabric and foam together in a strong bond.

Our laser welders are designed to be versatile and applicable for all purposes. No matter whether you are cutting small electronic parts or large pieces of metal, our machines will be able to process various types of materials with the same efficiency. This versatility is what makes our machines perfect for use in a diversity of industries,” such as cars and airplanes.

The laser welding technology from DMK has always been known for its speed and quality. The laser beam has high energy intensity, but the high power device takes welding time and welding speed is fast. It is good news for our customers as this ultimately means they can save time and money on process using our laser welding equipment.

Laser welding is the future of welding as technology improves. With its accuracy, speed and versatility, it is an ideal option for many industries in need of better welding. In this technology DMK is ahead of the curve ensuring we keep it this way by continually developing and looking for new ways to improve our laser welding machines for our customers.

Getting a DMK laser welding system offers you many benefits, one of which is that you end up with stronger, cleaner welds. The focused laser beam ensures that every weld is carried out with minimal distortion and gas pockets, and makes a clean and robust bond between the materials. That’s key in industries in which weld quality is critical, such as medical or aerospace applications.

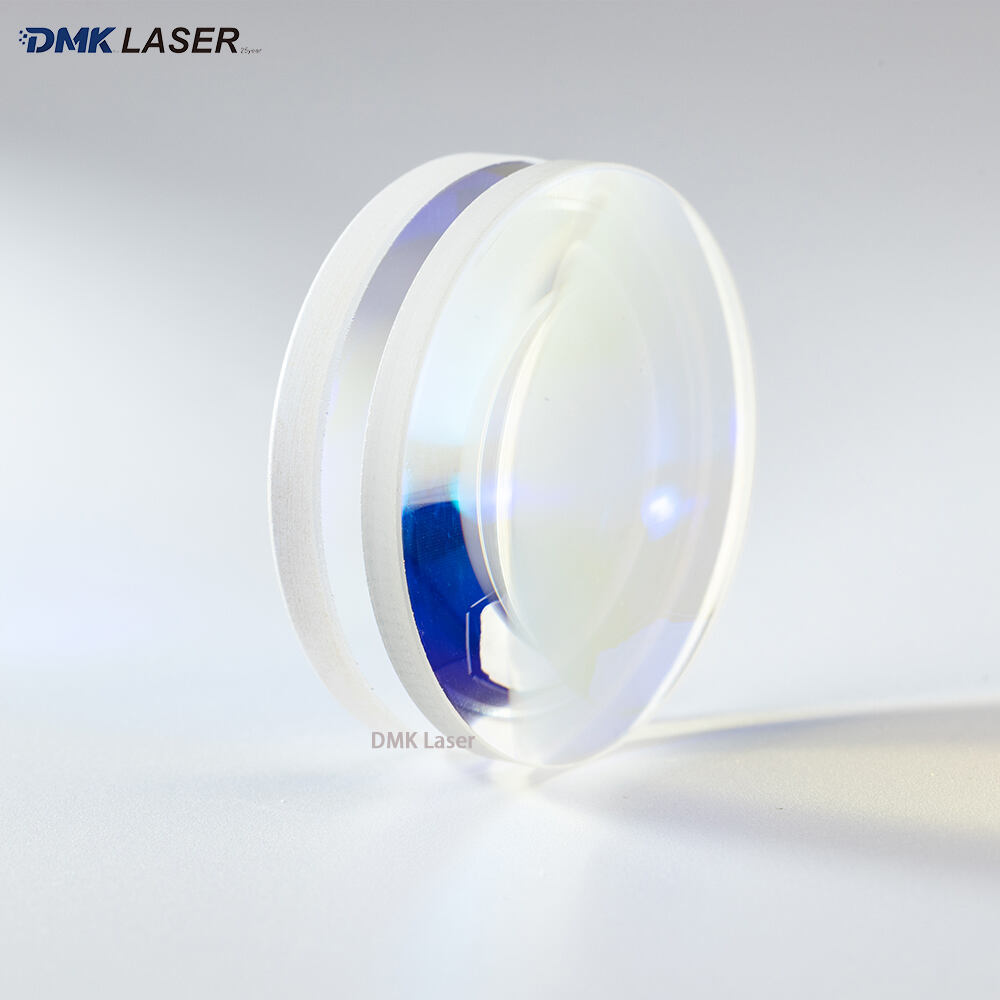

We now have integrated the most laser that is present into our procedures. Working with the top American vendors of laser devices and control systems like Raycus, MAX, JPT, Friendess, Raytools, SUP, QILIN, and ESTUN we are committed to supply the markets with the more laser that are economical welding, cleaning, cladding, and marking equipment. We very carefully select the elements we use for our laser equipment. We additionally control assembly processes and perform optic laser welding machine which are thorough. We assist Chinese manufacturers to provide better lives for global people with our efforts.

DMK try situated in the East Lake High-Tech Development Zone (Optics Valley) positioned in Wuhan, China. Our company is a company that are highly-tech are expert in research, development, and manufacturing of complete sets of laser equipment. We now have a few dozen postgraduates and researchers in our creator's team. With our contemporary manufacturing center for laser equipment, along with a skilled staff that is after-sales can afford to provide custom solutions for optic laser welding machine processing equipment to domestic and worldwide users. We offer the professional service which was after-sales resolve any product-related problems quickly.

We always adhere to the core values of "customer-centricity" and "creating customer-satisfying benefits." We place customer specifications near the top our range of priorities. Our company is individuals being active the "Made in China 2025 initiative" and use technology and services to upgrade the laser industry intelligently. Motivated due to the two forces for the Internet+ and Industry 4.0 that people are closely aligned with demands of this Internet that are industrial age. We provide the absolute many optic laser welding machine that is advanced technology and application service in the marketplace, and get together with our partners to achieve greater speeds, additional cost-effective and faster growth.

Our company possesses an offer that was considerable which comprises 8 biggest types of products and the selection which is big of, such because complete machines for laser cutting, laser welding, and laser cleansing. We furthermore have actually equipment like fiber lasers and laser minds. Our things are widely used in industries like sheet metal processing because well since equipment for ecological protection. Additionally, they find use in the industries of {keyword}, shipbuilding’s and aerospace, together with new shipbuilding and power. Our products, which may import and export independently and are growing in the share of this marketplace internationally in regions like East Asia, North America and Latin America, Middle East, Western Europe and Russia.