Laser wire feed welding is a cool process that allows two pieces of metal to be attached using a powerful beam of light. The technology is widely used in locations like car factories, construction sites and other places of fabrication. What kinds of advantages that the laser wire feed welding machine has, how can it be favored by the majority of workers compared with the old welding methods.

Laser wire feed welders heat wire, which passes through a nozzle, by a powerful laser beam. This will bond two pieces of metal together, producing a strong and durable joint. The laser beam is controlled by a computer so the welding can be extremely precise.

One of the biggest advantages to a Laser cleaning machine for rust removal is how quickly you can finish welding jobs. The wire is melted by the laser beam at a high speed, which achieves a quick operation. Further, laser welds have a clean and neat appearance, so there’s less finishing to do afterward.”

Laser wire feed welders are highly efficient as they do not have to work over the same spot repeatedly and can handle a variety of metal thicknesses. This is a time and labor saving step, and also reduces the chances of welding related mistakes. The laser is controlled directly by the computer so as welds are always the same and are always correct.

Laser wire feed welding is employed in a variety of industries. These welders are used in car assembly to join car parts. For construction, they can form into strong, hard joints in metal structures. Laser wire feed welders are also used by manufacturers to rapidly assemble metal parts.

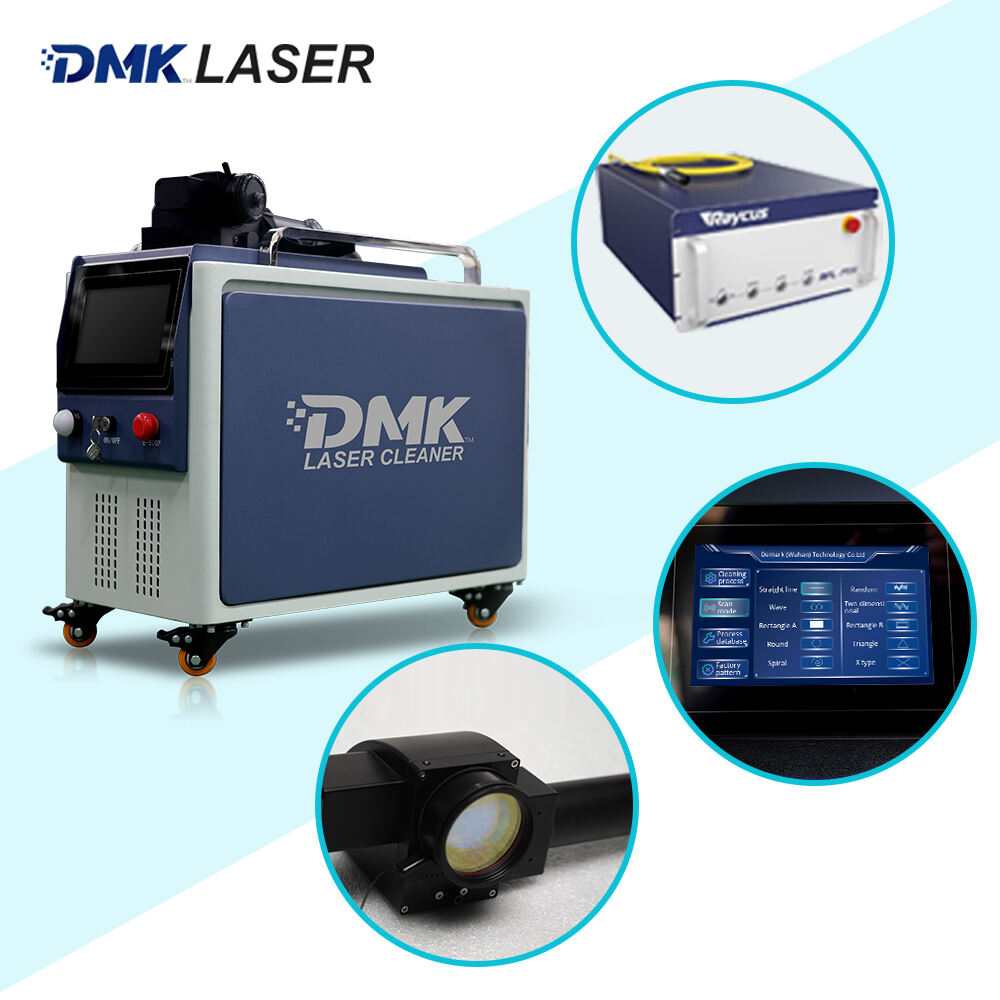

There are some key factors to consider when you are choosing a laser wire feed welder. Find a machine with adjustable power settings, so that you can modify the welding process based on metal thicknesses. An easy-to-use interface is also crucial, so the welder is friendly for novices to use. Also consider whether the welder has safety features, such as an automatic shutoff if it overheats.

We constantly adhere to the core values of "customer-centricity" and "creating customer-satisfying benefits." With customer needs during the very priority which is top we actively exercise the "Made in China 2025" initiative and leverage technology and services to aid in the efficient update concerning the laser industry. Our company is driven due to the twin forces of Internet+ and Industry 4.0 to feel in tune with modern needs connected with the era that is laser wire feed welder. You can expect the essential laser that is modern technology and application service in the markets, and perform with our partners to achieve greater efficiency, speedier and faster growth.

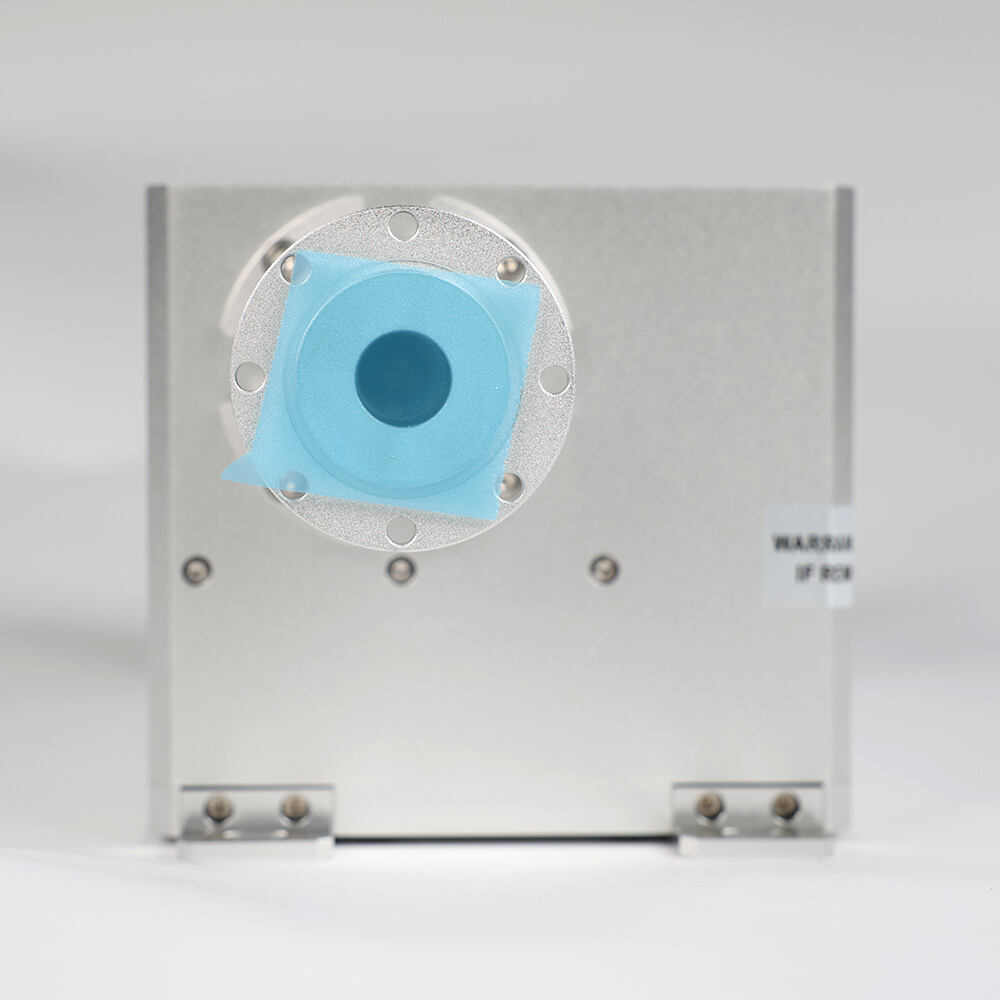

Presently, our company has generated a supply chain which covers eight biggest areas and lots of products that add complete machine production of laser machines that is cutting laser machines which is welding cleansing machines and the supply of elements fiber which are including cutting minds for lasers, laser welding minds since laser cleaning head and laser control systems. Our products are commonly used in industries such as for instance for example sheet metal processing and protection that are {keyword} which is agricultural shipbuilding, aerospace, and energy that will be additionally new. The Middle East, Western Europe, and Russia with the capability to export and import goods minus restriction our merchandise have won more market share in international areas like East Asia, North America, Latin America.

DMK try situated in the East Lake High-Tech Development Zone (Optics Valley) positioned in Wuhan, China. Our company is a company that are highly-tech are expert in research, development, and manufacturing of complete sets of laser equipment. We now have a few dozen postgraduates and researchers in our creator's team. With our contemporary manufacturing center for laser equipment, along with a skilled staff that is after-sales can afford to provide custom solutions for laser wire feed welder processing equipment to domestic and worldwide users. We offer the professional service which was after-sales resolve any product-related problems quickly.

With the constant development of fiber laser technology, we have included laser wire feed welder that is world-class and procedures. We partner with a few of the most reputable laser that are domestic and control system vendors like Raycus MAX, JPT Friendess Raytools SUP QILIN ESTUN. From the professional's view of laser processes, we carefully select every component of our equipment, strictly control construction processes, and conduct thorough inspections of the factory. We assist Chinese manufacturers to create better life for the world's consumers by this work.