For creating fine-looking jewellr, precision matters so much. It all adds up: the size of the gemstones — the design. Here is where a laser welding machine enters the picture. This special tool helps a jeweler to make flawless pieces very accurately.

A strong laser beam now welds their metals together. For jewelry making, this technique makes it possible to link up metal parts without harming elsewhere. It takes work to be good at it, but if you do, it’s incredible.”

Jewelers used plain soldering in the past to attach pieces of a piece of jewelry together. And now, with laser welding machines, things are very different. These machines enable jewelry to be made more quickly and precisely, so the pieces are nicer and the buyer is happier.

A primary advantage of the laser welding machine is that it can work on detailed work pieces. The machines can do the job whether it is a fine chain or a fancy setting. They’re so perfect in each piece.

Laser welding allows jewelers to experiment with new designs like never before. They can make fancy designs, special shapes and new styles, thanks to accuracy of these machines. Options abound for making special pieces that will impress customers.

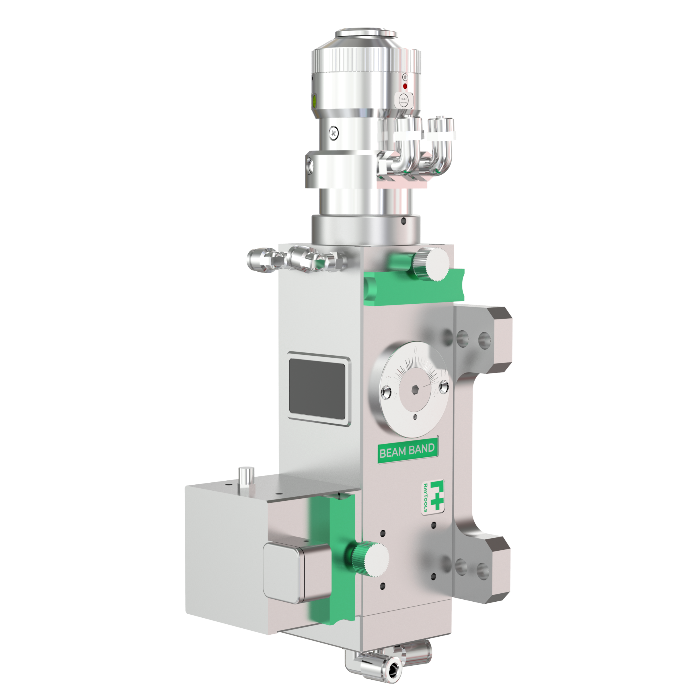

We now have integrated the most laser that is present into our procedures. Working with the top American vendors of laser devices and control systems like Raycus, MAX, JPT, Friendess, Raytools, SUP, QILIN, and ESTUN we are committed to supply the markets with the more laser that are economical welding, cleaning, cladding, and marking equipment. We very carefully select the elements we use for our laser equipment. We additionally control assembly processes and perform laser welding machine for jewelry which are thorough. We assist Chinese manufacturers to provide better lives for global people with our efforts.

DMK is found within the East Lake High-tech Development Zone in Wuhan. We have been an enterprise which are technical in analysis, development and manufacturing of complete laser welding machine for jewelry. We have a real quantity of scientists and postgraduates on our creator's team. We now have the state-of-the-art production facility for laser equipment and a group comprised of after-sales professionals whom can afford to offer custom solutions to customers in the international and market which is domestic. We furthermore offer expert help that was after-sales help clients solve any product-related problems promptly.

We constantly adhere to the core values of "customer-centricity" and "creating customer-satisfying value." We consider client needs as the concern that is main our selection of priorities. We earnestly take part in the "Made in China 2025 initiative" and utilize technology and services to help raise the laser markets in a means which are smart. Driven due to the dual forces regarding the Internet+ and Industry 4.0 We closely complement the needs connected with the Internet that is industrial era. We provide the essential laser that is laser welding machine for jewelry in choice to application service when you are able to find along with get together with our partners to attain greater efficiency, speedier and faster development.

Our company presently includes a supply chain that features eight major kinds of goods and loads of items, such as for instance for example machines which are complete can be used for laser cutting, laser welding, and laser cleansing, in choice to equipment like {keyword} in addition to laser heads. Our items can be used in industries such as for instance for instance sheet metal processing protection which is also ecological vessels, agricultural equipment, aerospace, in choice to power which is new. Our products, that are able to export and import individually and are growing in the share of forex trading that are regions which are global because East Asia, North America and Latin America, Middle East, Western Europe and Russia.