A laser rust removal gun is a unique machine to assist you to join metal tubes together with a high strength and rapidly! At DMK, we put those machines to work making cars, bikes, even playground equipment.

Laser tube welding machines melt metal tubes together with a special type of light. This creates a strong bond and is fantastic when making things that need to be strong, such as a bike frame or car body! The laser beam is the opposite, a super hot flashlight that can be very carefully aimed to make very precise welds.

One of the greatest advantages of Laser cleaning machine for rust removals is that they can help to speed the production process. This is to say that these are quick and easy to make. Standard techniques are time-consuming, and they require a lot of work, compared with new methods, such as laser tube welding, which can be used to achieve perfect welds in a fraction of the time. This, in turn, helps companies like DMK make more of their product faster, and therefore keep costs down and production running seamlessly.

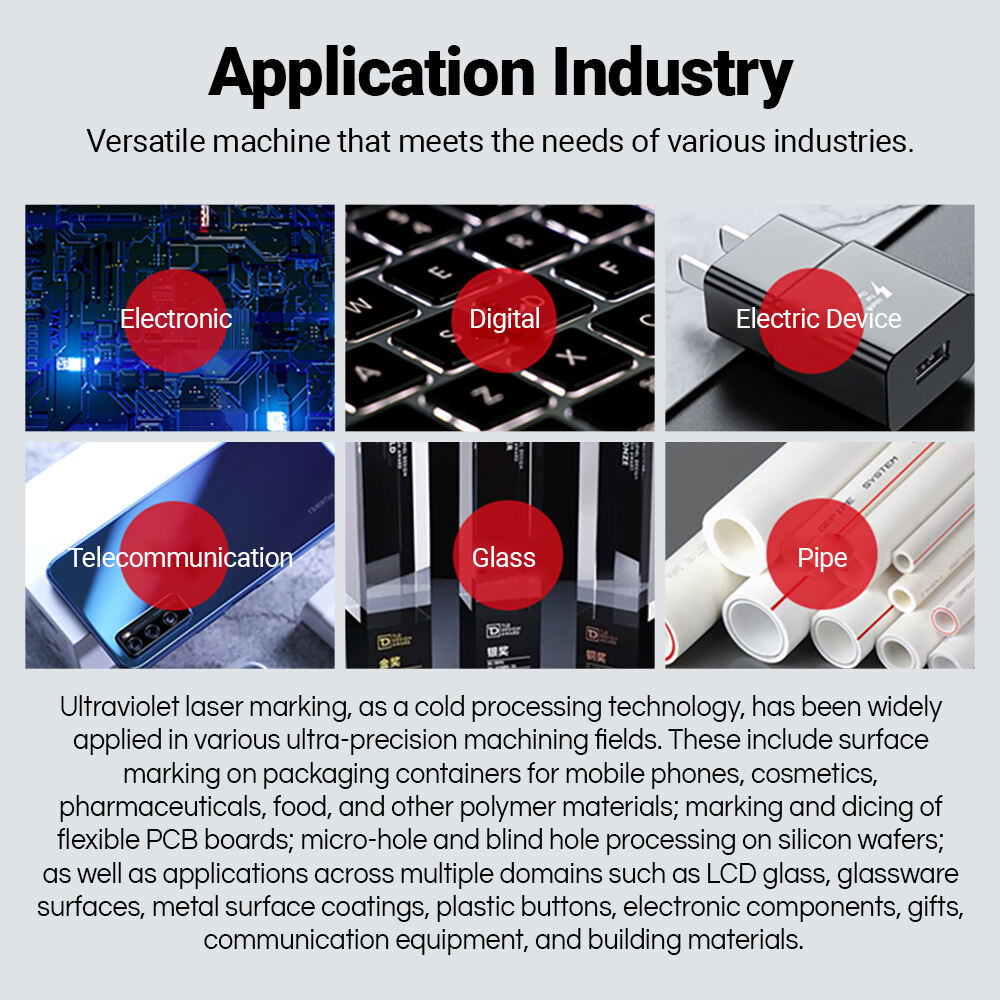

Polishing the stainless steel can increase speed up to 20-30m/min, thus generating more efficacy for laser welding. Laser tube welding machines can weld various metal tubes together. Whether its a large, thick tube to a small thin tube, the size of the laser beam can be tailored to the size and thickness of the metal resulting in a perfect weld time after time. This versatility makes laser tube welding machines relevant to a variety of industries, ranging from automobiles to airplanes.

One of the largest advantages of having a laser tube welding machine is how quickly it can produce welds. Welding is generally known to be slow, but a laser tube welding machine can make welds in seconds. This rapid welding leads to faster manufacturing, so products can be ready for customers more quickly.

We now have incorporated the laser technology that is current into our procedures. We work with leading laser tube welding machine which is domestic and control system providers like Raycus MAX, JPT Friendess Raytools SUP QILIN ESTUN. From the professional's viewpoint in laser procedures we bring care to choose every component for our equipment, monitor assembly processes carefully and conduct thorough inspections of the factory. With these efforts help us enable Chinese manufacturing to enhance the lives continuously of worldwide consumers.

Currently, our company has the supply chain encompassing 8 areas that are main a range that is big of these because the production that are complete of cutting machines, laser welding machines, laser cleansing machines, and the strategy of getting elements like fiber lasers, cutting lasers, laser welding minds, laser cleansing minds, also as laser control systems. Our products are commonly used in industries such as for instance sheet {keyword} processing and protection which is environmental vessels, agricultural machinery, aerospace, and the development of new energy. The Middle East, Western Europe and Russia with the capacity to import and export items that have accumulated a share that keeps growing of marketplace in international markets, such as for instance for instance East Asia, North America, Latin America.

We constantly adhere to the core values of "customer-centricity" and "creating customer-satisfying benefits." We give consideration to consumer specifications towards the top of your number of priorities. We actively take part in the "Made in China 2025 initiative" and use technologies and services to upgrade the laser industry intelligently. Inspiring by the two forces of Internet+ and Industry 4.0 and Industry 4.0, we closely proceed with the needs that is due to the Internet which was industrial age. We provide the important advanced level laser tube welding machine and application-related services in the business and collaborate with our supply chain to assist clients get faster, better, and additional growth which is effective.

DMK is found inside the East Lake High-tech Development Zone in Wuhan. We are the enterprise which was high-tech specializes in studies, development and manufacturing of complete sets of laser equipment. The group that founded us is created upwards of postgraduate level holders, and we hire a staff comprised of over a dozen scientists which are technical. We have a state-of-the-art production center for laser equipment in addition to a team of after-sales specialists which can provide personalized options to clients in the domestic and market that is international. We provide professional after-sales service for any nagging issue associated to the merchandise promptly.