Laser welding machines are increasingly being used in the welding industry and particularly when working with aluminium. These special machines have a laser beam that can joints pieces of aluminium together to produce a strong and durable weld.

Precision Is One of the Reasons You Should Use a Laser Welding Machine for Aluminium One major reason for which most industries looking get maximum productivity with the least down time use laser welding machine for aluminium is the precision that the process offers. The laser beam can be precisely manipulated, aiding in the production of clean and precise welds. This precision is crucial in industries such as aerospace and car making, where quality counts for a great deal.

Aluminium laser welding machines are famous for strong and durable welds. The intense heat from the laser causes the aluminium pieces to melt together and form a bond that is as strong as the metal itself. This strength is particularly important in areas where the welds have to take a lot of stress or stress.

Apart from their accuracy and efficiency, there are other advantages to Rust remover machines as well. They perform so fast and quick that weld is fast and economical. They don’t produce much waste, either, which is nice for the environment. This is a great way for manufacturers to shrink their carbon footprint.

Aluminium laser welding machines continues to be a growing part of manufacturing in each country due to the fact that they are strong, precise and efficient. They are used to create everything from car parts to aircraft components, transforming how innovative products are manufactured.

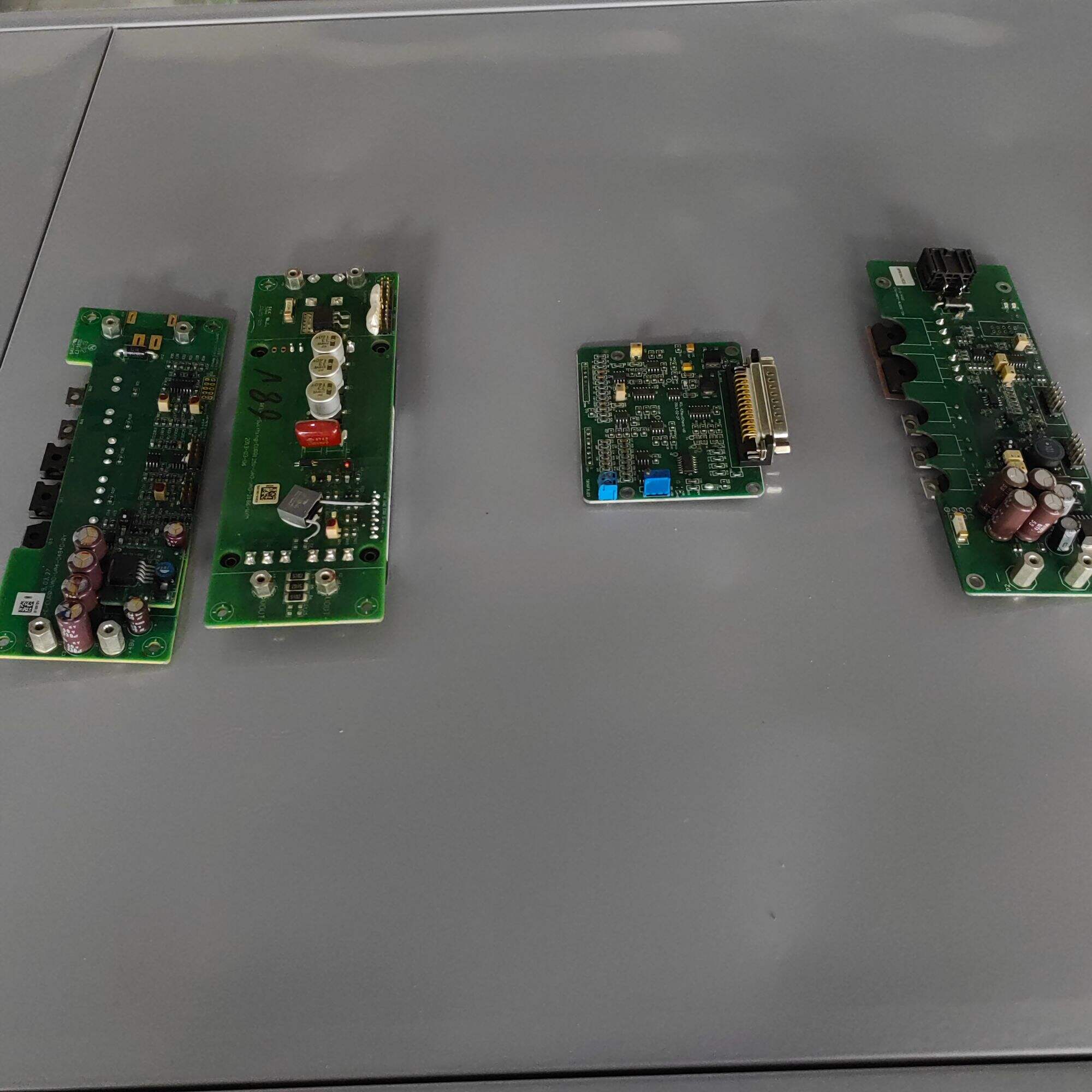

Our company possesses an offer that was considerable which comprises 8 biggest types of products and the selection which is big of, such because complete machines for laser cutting, laser welding, and laser cleansing. We furthermore have actually equipment like fiber lasers and laser minds. Our things are widely used in industries like sheet metal processing because well since equipment for ecological protection. Additionally, they find use in the industries of {keyword}, shipbuilding’s and aerospace, together with new shipbuilding and power. Our products, which may import and export independently and are growing in the share of this marketplace internationally in regions like East Asia, North America and Latin America, Middle East, Western Europe and Russia.

We always adhere to the core values of "customer-centricity" and "creating customer-satisfying value." We think about customer needs near the top of our priority list. We earnestly take part in the "Made in China 2025 initiative" and utilize technology and services to assist in enhancing the efficiency linked with the aluminium laser welding machine. In line with the twin force of Internet+ and Industry 4.0 and Industry 4.0, we closely proceed with industry needs for the Internet that was industrial age. You may expect the important laser that is advanced level technology and application service in the business and collaborate with our lovers to achieve greater speeds, additional cost-effective and quicker growth.

DMK is situated inside the East Lake High-tech Development Zone in Wuhan. We're the firm which are highly-tech concentrates on research, developing and production of complete sets of aluminium laser welding machine. We have true range postgraduates and scientists in our creator's group. We have production which was modern for lasers and a group comprised of after-sales specialists whom can afford to provide custom solutions to customers in the market in both nations. We offer professional after-sales services to solve any problems being product-related.

Due to the fact world continues to advance in aluminium laser welding machine technology, we've included laser which is world-class and procedures. In collaboration with top suppliers in the US of lasers and control systems, such since Raycus, MAX, JPT, Friendess, Raytools, SUP, QILIN, and ESTUN We are dedicated to provide affordable laser cutting to our customers, welding, cleaning, cladding, and marking tools. From the professional's attitude, in laser procedures, we carefully choose each element of our equipment, rigorously monitor assembly processes, and conduct rigorous inspections of the factory. With these efforts we can allow Chinese manufacturing to continue to give a better experience for global consumers.