Laser Welding Robots: The Greatest Solution for Efficient and Safe Welding

Are you sick and tired of the welding that are handbook that takes many years to accomplish which is not so accurate? Well, here is some given information which can be great you: the DMK laser welding robot has arrived to revolutionize their welding procedure! we will talk about the importance, innovation, security, utilize, utilizing, provider, quality, plus application of laser welding robots.

Laser welding robots provide a couple of benefits set alongside the conventional welding procedure that was handbook. First of all, the strategy was considerably constant plus exact, which eliminates mistakes plus decreases wastage associated with time plus components. Next, it was faster than handbook welding, which grows effectiveness plus efficiency. Thirdly, DMK laser welding creates less temperatures, reducing the likelihood of product distortion and warping. Finally, it may weld a variety that are wide of love metals, plastic materials, plus composites.

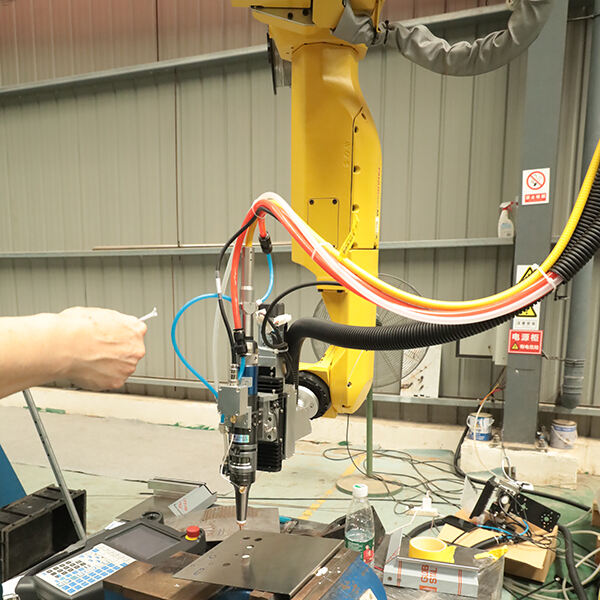

Laser welding robots actually are a game-changer in the welding business, plus their innovation try commendable. These robots make use of a laser that has been high-powered melt the content plus kind stronger welds. The laser's beam is targeted with a high accuracy, making a spot which was smaller of temperature which melts this product. The DMK rust removal with laser is managed to modify the ability full figured to fit items being thicknesses that are various.

The security of employees is truly an issue which was top any welding procedure. DMK laser welding robots need a few protection qualities that ensure chances which are minimal the operators. To begin with, the robots is enclosed, meaning that the laser beam stays within the robot. 2nd, the protection try have by the robots system that shuts from the laser in case there clearly was an situation that is urgent. Third, they will have sensors which identify any obstructions in the course connected with laser beam and steer clear of the strategy in order to avoid any injuries.

Laser welding robots may be used in a variety of companies like automotive, aerospace, medical, plus electronic devices. They've been appropriate welding components which are little sensors plus connectors to big structures like automobile figures plus airplane wings. The DMK rust cleaning laser could be programmed to weld in various jobs, perspectives, plus levels, creating them versatile plus adaptable to applications which are various.

Our company has a supply chain which include 8 biggest categories of products too as the selection that was big of things like complete machines which may be used for laser cutting, laser welding and laser cleaning, in selection to components such as for example dietary fiber lasers and laser minds. Our products are generally used in industries such since for instance sheet metal processing equipment for environmental protection, delivery, agricultural equipment aerospace, and {keyword} that is also new. Our merchandise, that may manage to import and export independently, have share which keeps growing of world marketplace throughout regions such because East Asia, North America and Latin America, Middle East, Western Europe and Russia.

We always adhere to the core values of "customer-centricity" and "creating customer-satisfying benefits." We put client service first on our concern list. We actively participate in the "Made in China 2025 initiative" making use of tools and services that assist modernize the Laser welding robot effectively. Our company is afflicted with the dual forces Internet+ and Industry 4.0 to adapt ourselves to the needs of the internet era that are industrial. You are able to expect the fundamental laser that are advanced technology in addition to application service that one may find along with work with our partners to attain greater speeds, more economical and quicker development.

DMK is situated in the East Lake High-tech Development Zone (Optics Valley) located in Wuhan, China. We're a company that are high-tech on research, development, production and sales of complete laser equipment. We need a few dozen researchers and postgraduates on our creator's team. We've a manufacturing that was modern for laser equipment and the team of after-sales professionals that are able to provide Laser welding robot for customers on both industry in both nations. We offer a professional help that is after-sales any issues relevant to items quickly.

With the constant development of fiber laser technology, we have included Laser welding robot that is world-class and procedures. We partner with a few of the most reputable laser that are domestic and control system vendors like Raycus MAX, JPT Friendess Raytools SUP QILIN ESTUN. From the professional's view of laser processes, we carefully select every component of our equipment, strictly control construction processes, and conduct thorough inspections of the factory. We assist Chinese manufacturers to create better life for the world's consumers by this work.

Making usage of laser welding robots was efficient and easy. The action which are very first to plan the robot utilizing the welding parameters, such as for example laser energy, welding speed, plus beam size. Following the parameters is put, the DMK fiber laser cleaning machine will begin welding the section that is proper. The operator best has got to monitor the task plus be sure that the robot try operating precisely. Furthermore, the operator might get a handle in the robot remotely, creating the method safer and much more comfortable.

Laser welding robots need regular repair to be sure efficiency which was durability that is optimal. The answer routine include cleaning the robot, checking the DMK handheld laser cleaner, plus changing any equipment and this can be worn-out. Regular servicing implies that the robot continues to be in good shape plus works at their most readily useful.

Laser welding robots create top-notch welds being stronger plus constant. The precision associated with the DMK buy laser rust remover implies that there was distortion which was minimal no importance of further finishing. Also, the grade of the weld reduce the possibility of any failure which are structural harm.