Посилення зростання: DMK Laser запрошує Relfar провести навчання з лазерного зварювання

Щоб далі підвищити Dmk лазер рівень знань і володіння новими портативними лазерними зварювальними продуктами серед співробітників, поліпшити їхню майстерність у використанні технології портативного зварювання, йти в ногу з розвитком галузі та зміцнити основну конкурентоспроможність компанії в лазерній галузі, Dmk лазер особливо запросили Головного інженера Лі, відповідального за Relfar , щоб провести професійне навчання на тему "Нові Портативні лазерні зварювальні продукти та технологія ручного зварювання" у навчальному класі на другому поверсі компанії 8 вересня. Співробітники активно зареєструвалися на тренінг, створивши на місці сильну навчальну атмосферу.

На тлі швидкого розвитку лазерних технологій, лазерна індустрія зустрічає безпрецедентно широкі перспективи. У міру того, як виробниче виробництво зміщується у бік високої точності, високої ефективності та екологічності, лазерні технології, завдяки своїм унікальним перевагам, все більше застосовуються в багатьох галузях, таких як металообробка, автомобілебудування, медичні прилади та побутова електроніка. Серед них — ручні лазерне зварювання та пристрої для прибирання , як важливі продукти застосування в галузі лазерних технологій, завдяки своїй гнучкості в експлуатації, високій якості зварювання, чудовому ефекту очищення, енергоефективності та екологічності стали ключовим обладнанням для вирішення традиційних проблем зварювання та очищення. Вони ефективно задовольняють ринковий попит на обробку складних виробів і високоефективну обробку поверхонь, при цьому попит на ринку продовжує зростати.

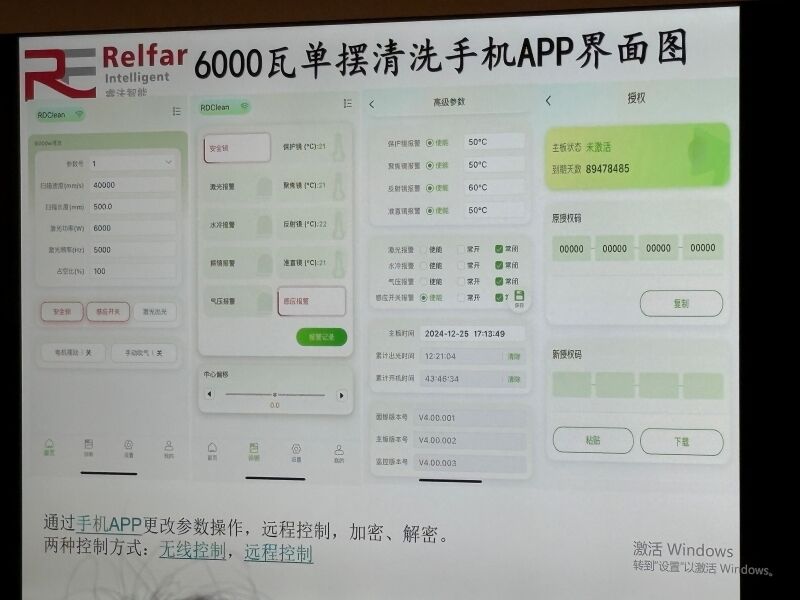

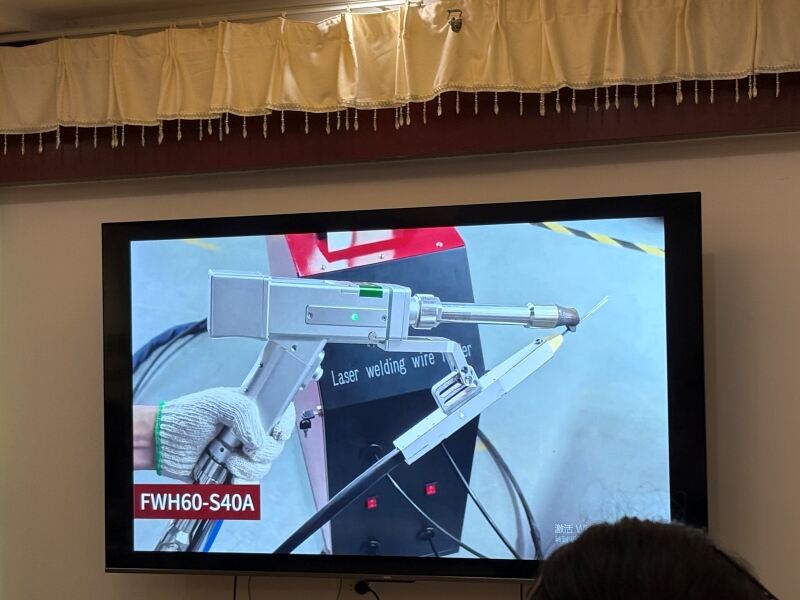

Зосереджено на представленні нових портативні лазерні зварювальні продукти , під час цього навчання провідний інженер Лі, використовуючи свій багаторічний досвід у галузі та професійні знання, дав працівникам детальне пояснення щодо кількох ключових продуктів. Серед них — машина зварювання та очищення з односкладовою осциляцією потужністю 6000 Вт, машина очищення з подвійною осциляцією та серія зварювальних машин з подвійною осциляцією, що мають три способи подачі дроту.

Щоб допомогти співробітникам краще зрозуміти характеристики продукту, Головний інженер Лі поєднав зображення, текст та відео в своєму поясненні. Ознайомлюючи із інтерфейсом мобільного додатка , він використовував наочні графічні зображення, щоб співробітники швидко засвоїли різноманітні функції та процедури роботи з додатком; водночас він демонстрував практичні відеоролики роботи машин, наочно показуючи методи роботи, процеси виконання та кінцеві результати обробки різних продуктів у реальних умовах застосування, що дало змогу співробітникам отримати більш повне та глибоке уявлення про продукти

|

|

Під час навчання працівники залишалися дуже уважними, уважно слухали пояснення та активно робили нотатки щодо ключових питань. Під час інтерактивної комунікаційної сесії всі ентузіастично висували запитання щодо експлуатаційних характеристик продукту, технічних складнощів у процесі зварювання та практичних сценаріїв застосування. Головний інженер Лі терпляче й докладно відповів на запитання кожного працівника, створивши жваву атмосферу на місці проведення комунікації.

Навчання дозволило персоналу DMK Laser глибоко зрозуміти переваги та технології нових портативних зварювальних лазерних продуктів і підвищило їхню професійну кваліфікацію. У майбутньому компанія посилюватиме співпрацю в галузі, організовуватиме регулярні навчальні сесії, поліпшуватиме навички працівників, сприятиме зростанню свого лазерного бізнесу та підтримуватиме інновації в лазерних технологіях.

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR