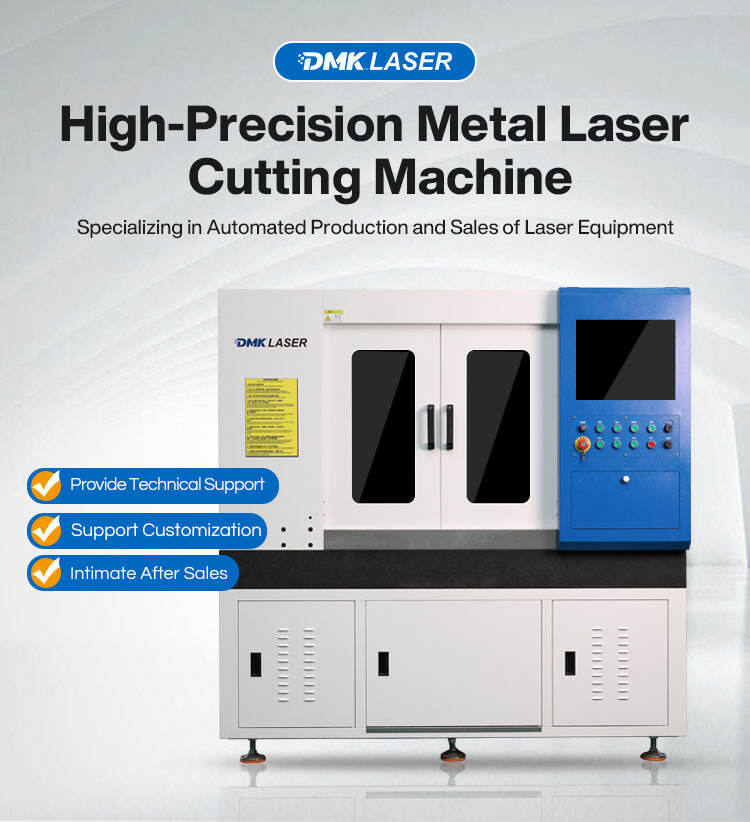

DMK 1000 Вт Високопотужний керамічний лазерний верстат для різання та свердління

Опис продукту

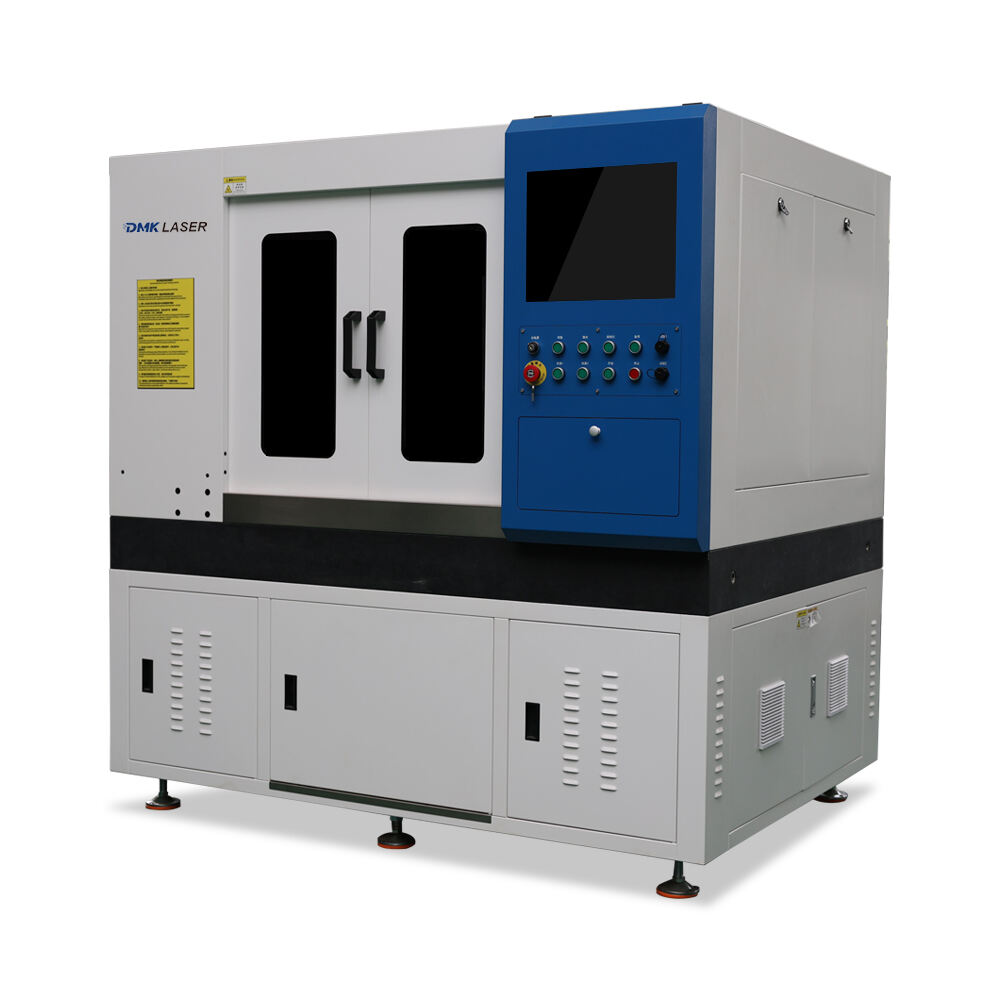

Верстат для різання та свердління кераміки лазером потужністю 1000 Вт призначений для високоточної обробки сучасної кераміки. Обладнаний сучасним користувацьким волоконним лазером, ця система забезпечує виняткову якість променя, компактну конструкцію та високу ефективність перетворення світла в електроенергію. З мінімальним технічним обслуговуванням, низькими експлуатаційними витратами та енергозберігаючими характеристиками, це ідеальний вибір для точного різання та свердління у вимогливих галузях.

Параметри продукту

| Специфікація | Деталі |

|---|---|

| Довжина хвилі лазера | 1060–1080 нм |

| Потужність лазера | QCW-1000 Вт |

| Робоча зона | 600 × 600 мм |

| Точність повторного позиціонування | ±5 μm |

| Швидкість обробки | 0–500 мм/с |

| Максимальна Швидкість Переміщення | 60 м/хв |

| Толщина різання | ≤ 8 мм (залежно від матеріалу) |

| Точність обробки | ±0,02–0,03 мм |

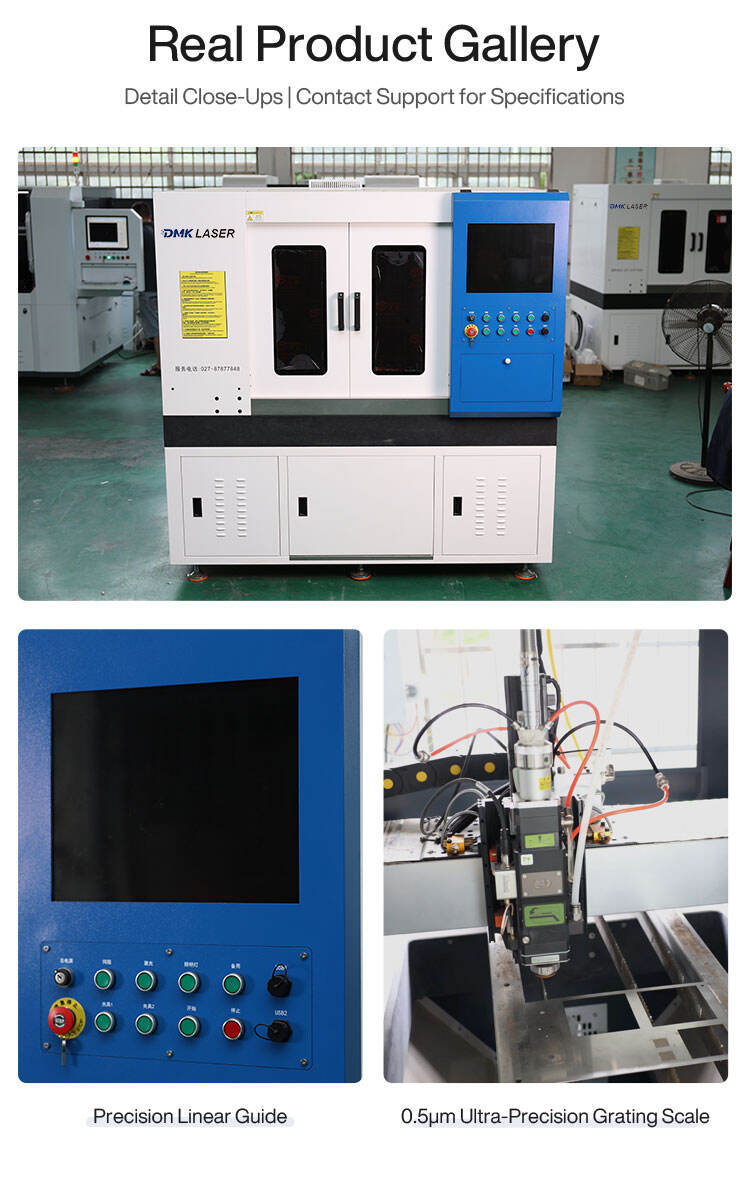

| Система приводу | Імпортний лінійний двигун + шкала ґратки 0,5 мкм |

| Споживання електроенергії (без вентилятора) | ≤ 8 кВт |

| Загальна вага | Приблизно 1800 кг |

| Розміри апарату | 1800 × 1470 × 1890 мм (залежно від фактичного продукту) |

Інші деталі

Основні особливості

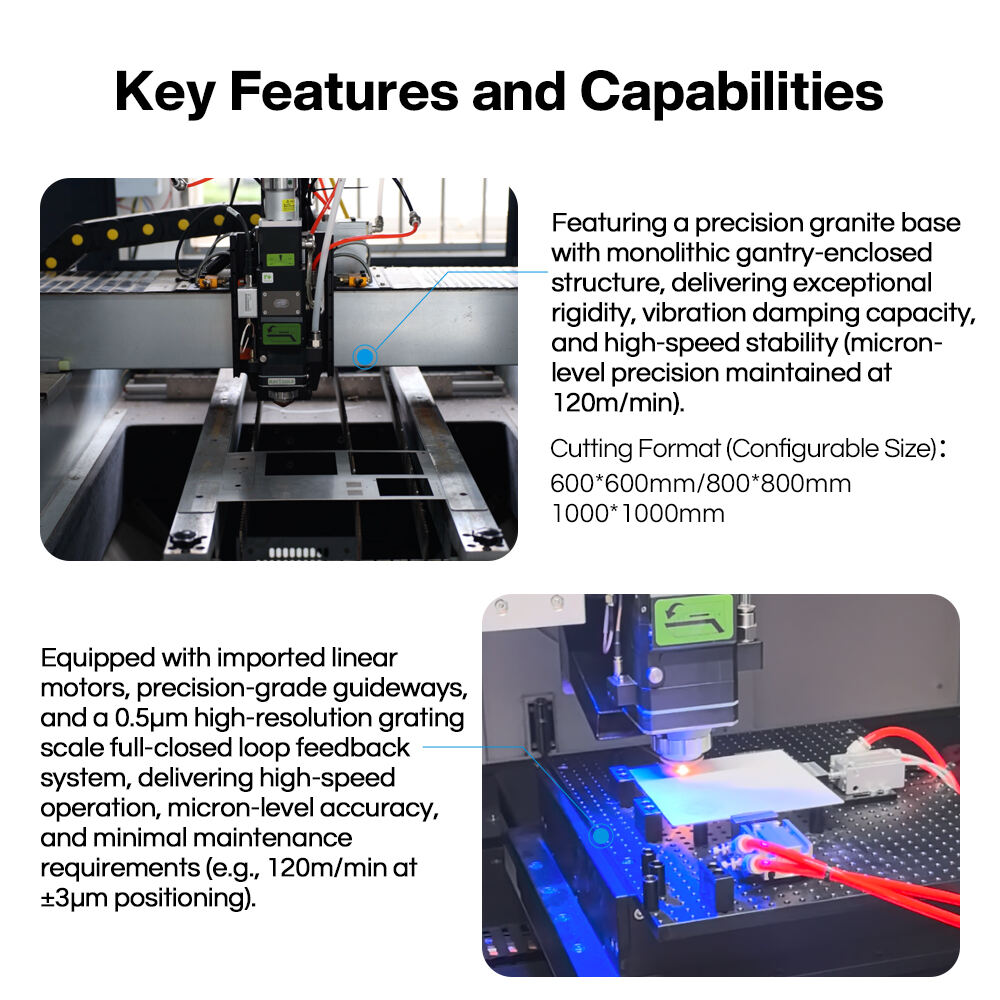

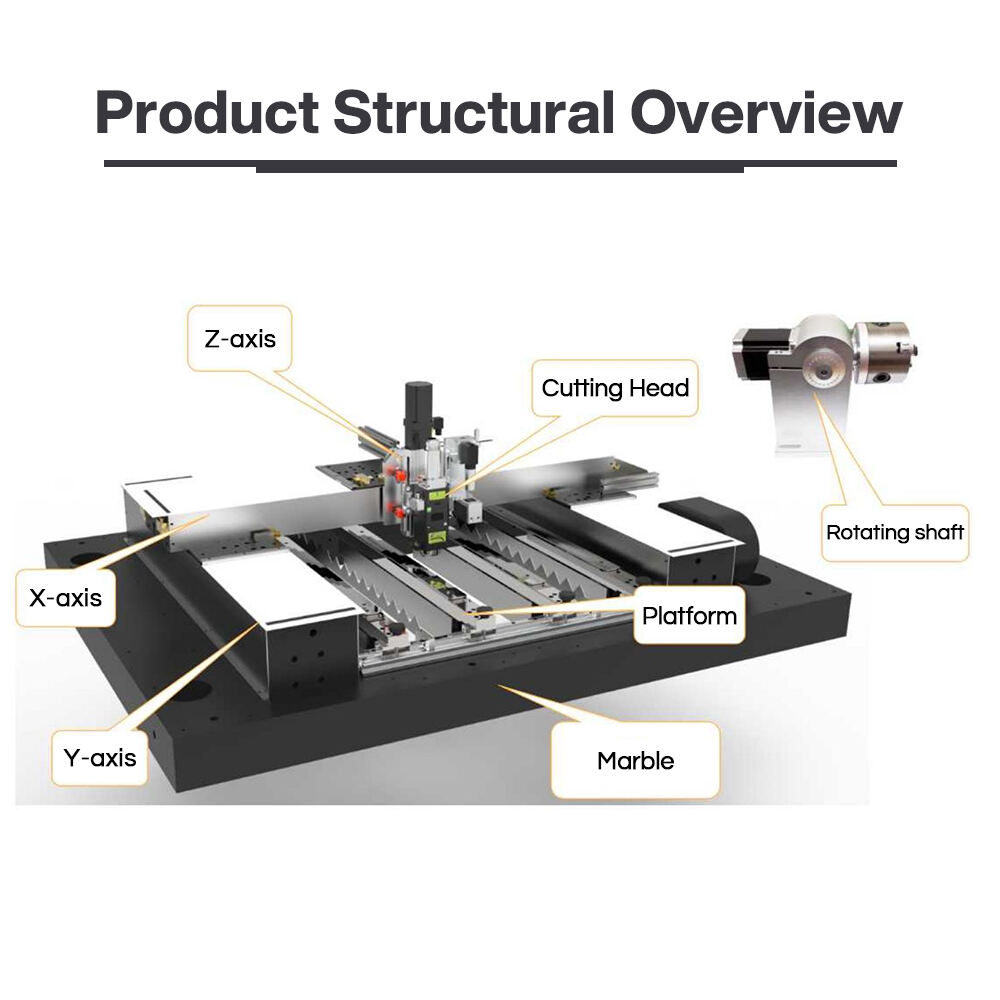

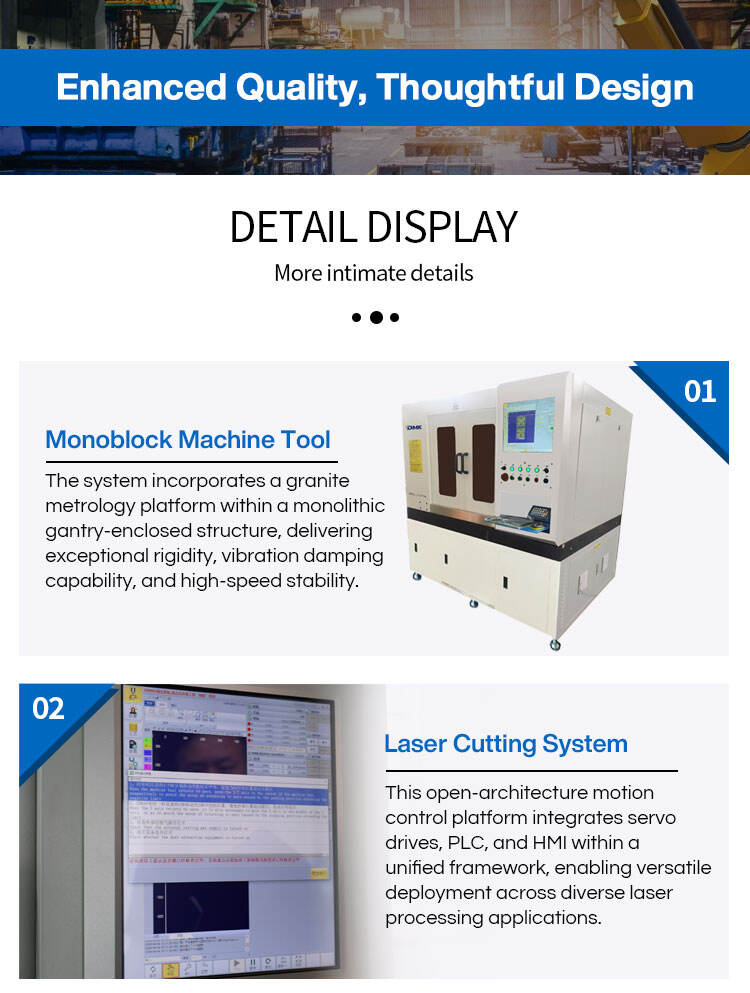

Високостабільна конструкція

Виготовлена з використанням прецизійної мармурової платформи та інтегрованої закритої конструкції типу ганtry для виняткової жорсткості, стійкості до вібрацій та стабільності на високих швидкостях.

Точна система руху

Використовує імпортні лінійні двигуни на магнітному підвішуванні, високоточні напрямні та повністю замкнену систему зворотного зв’язку з оптичними ґратками 0,5 мкм для виняткової точності та швидкості.

Спеціалізована лазерна конфігурація

Обладнана користувацьким волоконним лазером і прецизійною керамічною ріжучою головкою, що забезпечує вузьку щілину, чисті краї та різання без заусенців.

Надійне управління електроживленням

Включає вбудований стабілізатор напруги для захисту електронних компонентів, забезпечуючи безпечну та стабільну роботу.

Опціональна візуальна система CCD

Підтримує автоматичне розпізнавання контрольних точок для високоточної позиціонування й різання.

Презентація вибірки продукції

Застосування

Ця передова лазерна система оптимізована для різання й свердління широкого діапазону керамічних матеріалів, зокрема:

-

Алюміній оксид (Al₂O₃)

-

Цирконій оксид (ZrO₂)

-

Алюміній нітрид (AlN)

-

Силіцій нітрид (Si₃N₄)

З опціональною візуальною системою CCD також підтримує:

-

Розпізнавання контрольних точок

-

Маркування та різка металізованих керамічних матеріалів і чіп-субстратів

Широко використовується в галузях:

-

Медичні прилади

-

Авіаційно-космічна та військова промисловість

-

Точні компоненти у високотехнологічному виробництві

Індустріальні застосування

-

Промислові керамічні матеріали : Форми та конструктивні компоненти

-

Електронна промисловість (PCB) : Різка, свердління та маркування плат на основі міді/алюмінію та керамічних друкованих плат

-

Нова енергія : Сонячні фотоелектричні модулі, автомобільні сенсори, водневі паливні елементи з кераміки

-

3C промисловість : Керамічні задні кришки для мобільних телефонів, середні рамки, кришки сенсорів відбитків пальців, нагрівальні елементи для електронних сигарет

Інформація про компанію

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR