- Головна сторінка

- Продукти

- Про компанію

- Відео

- Застосування

- Новини

- Центр Допомоги

- Зв'яжіться з нами

Лазерна сварка з кормленням провідом - це цікавий процес, який дозволяє з'єднати дві частини металу за допомогою потужного променя світла. Ця технологія широко використовується в місцях, таких як автозаводи, будівельні строї та інші місця виробництва. Які переваги має лазерна сварка з кормленням провідом, і чому вона є більш популярною серед багатьох робітників порівняно з старими методами сварки.

Лазерні сварники з підачею проволоки нагрівають проволоку, яка проходить через дузю, потужним лазерним променем. Це спричинить з'єднання двох частин металу, створюючи міцне і тривале з'єднання. Лазерний промінь керується комп'ютером, щоб сварка могла бути надзвичайно точна.

Одна з найбільших переваг Лазерної чистки машини для видалення ржавчини - це наскільки швидко ви можете завершити сварочні роботи. Проволока розплавлюється лазерним пучком з високою швидкістю, що забезпечує швидку операцію. Крім того, лазерні шви мають чистий і аккуратний вигляд, тому потрібно менше закінчуючих робіт після.

Лазерні сварники з проволокоподачею дуже ефективні, оскільки їм не потрібно повторювати операції над тим самим місцем і вони можуть обробляти різну товщину металу. Це крок, який заощаджує час і працю, а також зменшує шанси на помилки, пов'язані зі сваркою. Лазер безпосередньо керується комп'ютером, тому всі шви завжди однакові і правильні.

Лазерна сварка з проволокоподачею використовується у різних галузях промисловості. Ці сварники використовуються при збиранні автомобілів для сполучення деталей автомобіля. Для будівництва вони можуть створювати міцні, тверді шви в металевих конструкціях. Лазерні сварники з проволокоподачею також використовуються виробниками для швидкого збирання металевих деталей.

При виборі лазерного сварочного апарату з кормленням провідом потрібно врахувати декілька ключових факторів. Шукайте машину з регулюванням потужності, щоб ви могли модифікувати процес сварки в залежності від товщини металу. Також важливим є простий у використанні інтерфейс, щоб сварочний апарат був зрозумілим для початківців. Розгляньте також, чи має сварочний апарат безпечні функції, наприклад, автоматичне вимикання при перегріванні.

Ми постійно дотримуємося основних цінностей «орієнтації на клієнта» та «створення вигод, що задовольняють клієнтів». Оскільки потреби клієнтів є найвищим пріоритетом, ми активно реалізуємо ініціативу «Зроблено в Китаї 2025» й використовуємо технології та послуги для ефективного оновлення лазерної галузі. Наша компанія рухається під впливом двох сил — «Інтернет+» та «Промисловість 4.0», щоб бути в унісоні з сучасними вимогами епохи лазерного зварювального апарату з подачею дроту. Ви можете очікувати на сучасні лазерні технології та сервісні рішення на ринках, а також співпрацювати з нашими партнерами для досягнення більшої ефективності, швидшого та стабільнішого зростання.

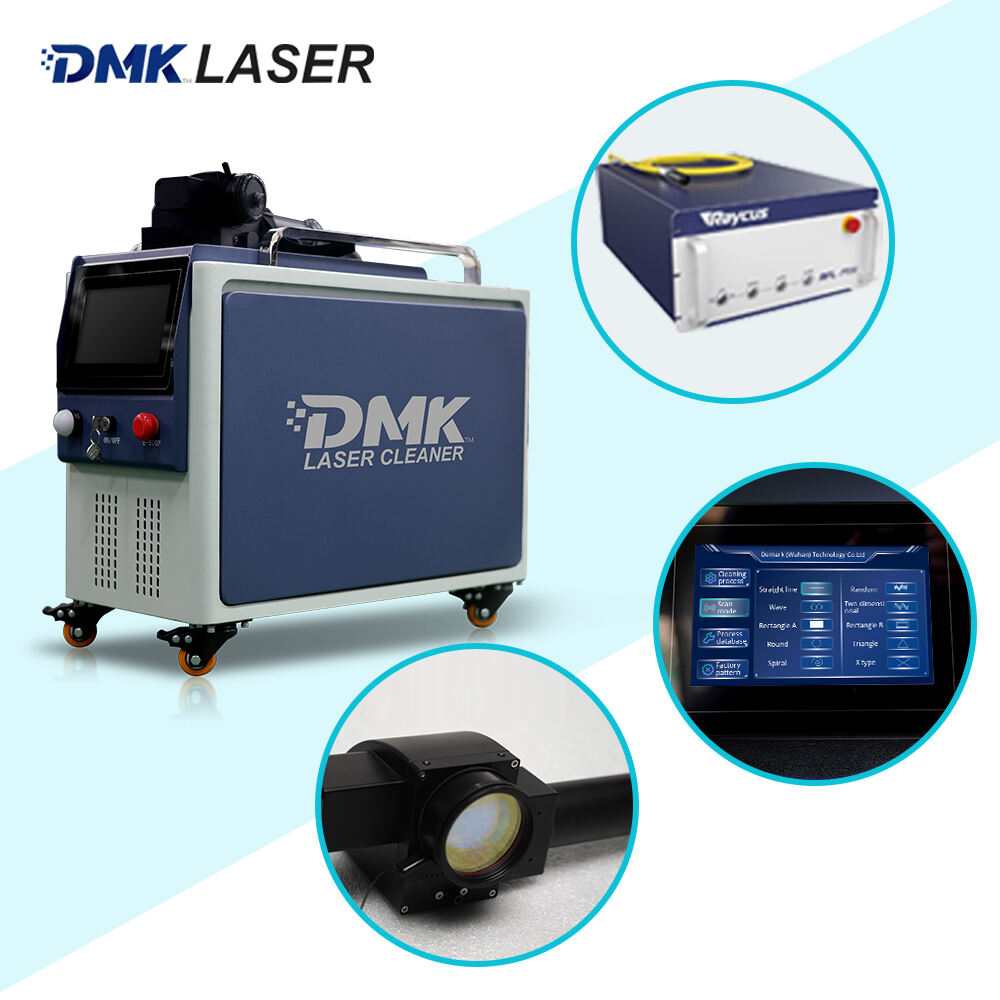

На даний момент наша компанія створила ланцюг постачання, який охоплює вісім найбільших регіонів та багато продукції, що включає повне виробництво машин лазерного оброблення, а саме різальних лазерних машин, сварювальних очисних машин і постачання елементів з волокна, включаючи режучі головки для лазерів, лазерні сварювальні головки та лазерні очисні головки, а також системи керування лазерами. Наші продукти широко використовуються в промисловостях, таких як, наприклад, обробка листового металу та захист, які {ключове слово} включають сільське господарство, будівництво кораблів, авіастроєння та енергетику, які також є новими. Близько Середнього Сходу, Заходньої Європи та Росії з можливістю експорту та імпорту товарів без обмежень, наші товари отримали більше частки ринку в міжнародних регіонах, таких як Східна Азія, Північна Америка, Латинська Америка.

DMK — це компанія, розташована в зоні високих технологій «Східне озеро» («Оптична долина») у м. Ухань, Китай. Наша компанія є високотехнологічною організацією, що спеціалізується на дослідженнях, розробці та виробництві повних комплектів лазерного обладнання. У нашій команді розробників працює кілька десятків кандидатів наук та науковців. Завдяки сучасному виробничому центру лазерного обладнання та кваліфікованому персоналу з післяпродажного обслуговування ми можемо надавати індивідуальні рішення щодо обладнання для лазерного наплавлення дротом як українським, так і міжнародним замовникам. Ми надаємо професійне післяпродажне обслуговування, що дозволяє оперативно вирішувати будь-які проблеми, пов’язані з продукцією.

З постійним розвитком технології волоконних лазерів ми включили у свою продукцію світового класу лазерний зварювальник із подачею дроту та відповідні технологічні процеси. Ми співпрацюємо з низкою найбільш авторитетних виробників лазерів та систем керування як вітчизняних, так і закордонних — таких як Raycus, MAX, JPT, Friendess, Raytools, SUP, QILIN, ESTUN. З професійної точки зору лазерних технологічних процесів ми уважно підбираємо кожну компоненту нашого обладнання, суворо контролюємо процеси виготовлення та проводимо ретельний заводський контроль якості. Цією роботою ми допомагаємо китайським виробникам створювати краще життя для споживачів у всьому світі.