- Ana Sayfa

- Ürünler

- Hakkımızda

- Videolar

- Uygulama

- Haberler

- Yardım Merkezi

- Bize Ulaşın

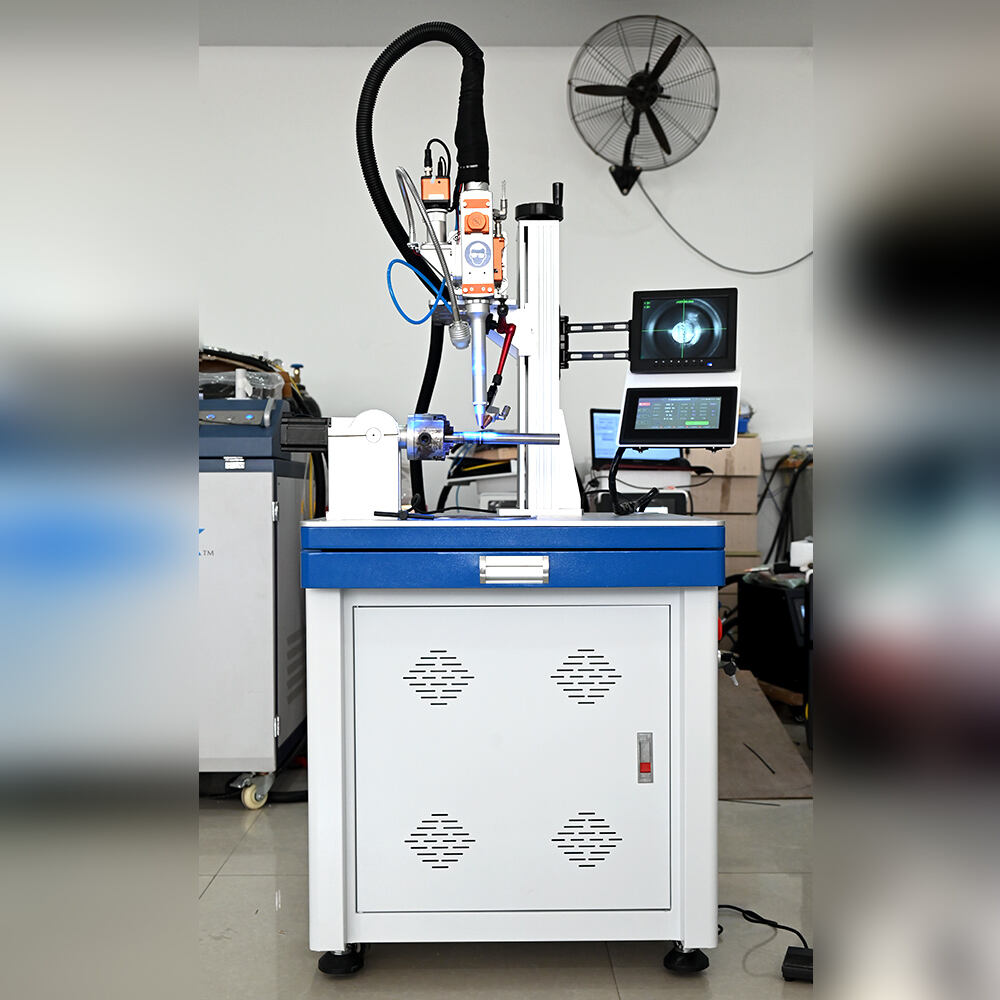

Lazer ışını kaynaklı mFu makine üreticileri inanılmaz makinelerdir ve bizi nasıl inşa ettiğimizde değiştirmektedir. Bu makineler, güçlü bir ışık demeti yayarak malzemeleri birbirine bağlıyor, bu süreç lazer olarak bilinir. Biraz sihir gibi gözüküyor, ama aslında bilim!

Geçmişte, kaynaklama sıcak alev veya elektrikli.spark kullanılarak gerçekleştiriliyordu. Bugüne gelindiğinde, lazer ışın kaynaklı kaynaklama makineleri bu işlemi daha hassas ve hızlı hale getirdi. Bu, daha iyi ve daha hızlı ürünler elde etmeye yol açabilir. Sanki fabrika bir süper kahraman sahipler!

Lazer ışını kaynaklı birleştirmede başka bir güzel özellik de normal koşullarda kolayca birleştirilemeyen malzemeleri birleştirebilmesidir. Nedeni nedir, bu bile alüminyum, titan ve bazı plastikler dahil eder! Lazer ışını bu malzemeleri bir araya getirmek için yeterince güçlüdür, ancak onları parçalamaz. En iyi yapıştırıcı gibidir!

Lazer ışını kaynaklı birleştirme makineleri, imalatın 'İsviçre Ordu Çantası'dır. Küçük cerrahi cihazlar kadar büyük uçağın gövdesi kadar çeşitli eşyalar üretebilirler. Lazer ışını o kadar hassas ki, ürünlerin detaylarına inebilirsiniz. Üretim hattında bir süper sanatçı varmış gibi!

Lazer ışını kaynaklı birleştirme makineleri fabrikalara daha hızlı, daha iyi ve daha ucuz şekilde şeyler yapma yeteneği vermiştir. Bu nedenle, daha kapsayıcı bir ekonomiye doğru daha ilerlemiş bulunmaktayız — daha fazla insanın bulabileceği ve satın alabileceği mallar ve hizmetler anlamına gelir. Biliyor musunuz, şu anda her şey olabilecek bir dünyada yaşıyorsunuz!

Şirketimiz şu anda sekiz en büyük alanı kaplayan bir tedarik zinciri oluşturdu ve tam bir makine üretimi ekleyen birçok ürün üretti. Lazer makineleri kesme lazer makineleri kaynak temizleme makineleri ve lazerler için kesme beyinleri, lazer temizleme başından beri lazer kaynak beyinleri ve lazer kontrol sistemleri de dahil

Her zaman "müşteri odaklılık" ve "müşteri memnuniyetini sağlayıcı faydalar yaratma" temel değerlerine bağlı kalırız. Müşteri spesifikasyonlarını önceliklerimizin en üst sıralarına yerleştiririz. Şirketimiz, bireylerin aktif olarak "Çin'de Üretim 2025 İnisiyatifi"ne katıldığı bir kuruluştur ve lazer endüstrisini akıllıca yükseltmek için teknoloji ve hizmetleri kullanır. İnternet+ ve Endüstri 4.0 olmak üzere iki güçlü etkenin harekete geçirmesiyle, insanlar bu dijital çağın endüstriyel taleplerine yakın bir şekilde uyum sağlamıştır. Pazarda ileri düzey teknolojiye sahip ve uygulama hizmeti sunan en kapsamlı lazer ışın kaynak makinesini sağlarız; ayrıca ortaklarımızla birlikte daha yüksek hızlara, daha maliyet etkin çözümlere ve daha hızlı büyümeye ulaşmayı hedefleriz.

DMK, Wuhan'da Doğu Gölü Yüksek Teknoloji Gelişim Bölgesi içinde yer almaktadır. Tam bir lazer ışın kaynak makinesinin analizi, geliştirilmesi ve üretiminde uzmanlaşmış bir işletmeyiz. Tasarımcı ekibimizde çok sayıda bilge ve yüksek lisans mezunu bulunmaktadır. Şu anda lazer ekipmanları için son teknoloji üretim tesisine ve uluslararası ile yerel piasada müşterilere özel çözümler sunabilen bir satış sonrası profesyoneller grubuna sahibiz. Ayrıca, ürünle ilgili herhangi bir sorunu müşterilere hızlıca çözmeleri için satış sonrası uzman destek hizmeti de sağlamaktayız.

Şimdi prosedürlerimize güncel lazer teknolojisini entegre ettik. Raycus, MAX, JPT, Friendess, Raytools, SUP, QILIN, ESTUN gibi yerli lider lazer ışın kaynak makinesi ve kontrol sistemi sağlayıcılarıyla çalışıyoruz. Lazer prosedürleri açısından profesyonel bir bakış açısıyla ekipmanlarımız için her bileşeni dikkatle seçiyor, montaj süreçlerini titizlikle izliyor ve fabrikada kapsamlı denetimler gerçekleştiriyoruz. Bu çabalarımız sayesinde Çin imalatının, dünya genelindeki tüketicilerin yaşam kalitesini sürekli olarak artırmasına katkıda bulunuyoruz.