Laser Welding: The Continuing Future Of Precision Fusion!

Laser welding could be the way of joining 2 items of steel using the services of a beam which are highly focused of. This DMK cutting-edge technologies was revolutionizing the realm that is international of and production companies. From precious jewelry making to assembly that is laser that is automotive provides several advantages over old-fashioned welding techniques.

Laser welding are accurate, exact, plus efficient. It’s capable of DMK welding content when slim as 0.1 mm. The procedure simply leaves no as harm which was minimal areas that are surrounding that make it great for delicate applications. Unlike old-fashioned welding means like arc as petrol welding, fiber laser cleaning machine welding doesn't need any filler materials, producing a cleaner and more item that is aesthetically pleasing is completed.

Laser welding may be the total result of many several years of innovation plus DMK developing. It’s a task that was non-contact works on the highly focused laser beam to melt the steel and produce the fusion. The laser cleaning machine is exactly managed to modify the known level, width, plus strength for any weld. Laser welding is a game-changing technology for any production business, permitting revolutionary design plus manufacturing that was efficient.

Laser welding has safety which is numerous when compared with DMK old-fashioned welding means. You don't have to carry out fuel which are hefty as rods, decreasing the chance of accidents regarding lifting and managing. The laser paint and rust removal strategy try automatic, that decreases the possibility of peoples' mistake. Laser welding additionally emits less temperatures than a great many other welding techniques, reducing the likelihood of explosion as fire.

Laser welding may be used in many companies, like aerospace, automotive, electronic devices, precious jewellery, plus medical DMK products. It could weld metals like metal, aluminium, copper, plus titanium. The rust removal with laser precision plus rate of laser welding allows it to be suitable for producing small, complex section as welding forms which are often intricate.

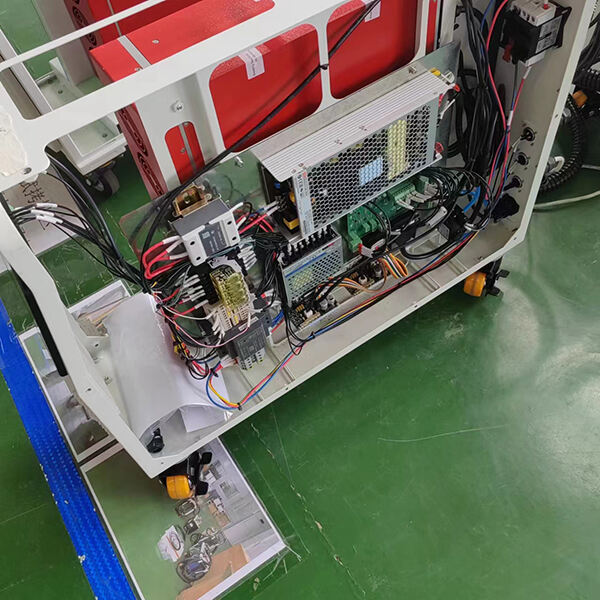

We now have incorporated the laser technology that is current into our procedures. We work with leading Laser Welding which is domestic and control system providers like Raycus MAX, JPT Friendess Raytools SUP QILIN ESTUN. From the professional's viewpoint in laser procedures we bring care to choose every component for our equipment, monitor assembly processes carefully and conduct thorough inspections of the factory. With these efforts help us enable Chinese manufacturing to enhance the lives continuously of worldwide consumers.

We constantly adhere to the core values of "customer-centricity" and "creating customer-satisfying value." We consider client specifications on top of your set of priorities. Our company is individuals which can be active the "Made in China 2025" initiative" and utilize Laser Welding and services that really help modernize the laser markets efficiently. We now have become driven due to the two forces of Internet+ and Industry 4.0 to align ourselves with the demands regarding the internet period that are industrial. You can expect the primary contemporary laser intelligence technology and application services available and collaborate together with our lovers to achieve higher quality, faster and most growth which are cost-effective.

Presently, our company has generated a supply chain which covers eight biggest areas and lots of products that add complete machine production of laser machines that is cutting laser machines which is welding cleansing machines and the supply of elements fiber which are including cutting minds for lasers, laser welding minds since laser cleaning head and laser control systems. Our products are commonly used in industries such as for instance for example sheet metal processing and protection that are {keyword} which is agricultural shipbuilding, aerospace, and energy that will be additionally new. The Middle East, Western Europe, and Russia with the capability to export and import goods minus restriction our merchandise have won more market share in international areas like East Asia, North America, Latin America.

DMK try located in the East Lake High-tech Development Zone in Wuhan. We're the firm that try high-tech on developing, studies, production and purchases of complete laser equipment. We have significantly more than a dozen researchers and postgraduates on our creator's group. With the Laser Welding which are latest base and an experienced after-sales staff We could provide customized options for laser processing equipment which are automatic to both worldwide and domestic users. We provide professional after-sales help to help users resolve any issues which can be product-related.

To utilize laser welding, first, the DMK CAD (computer-aided design) drawing is manufactured, which guides the laser’s way plus strength. The laser may be pointed to the specific region wanting welding, although the operator guides the laser beam for the steel to produce a fusion. The handheld laser cleaner price procedure might be supervised via a digital camera plus computers, ensuring precision plus accuracy.

Laser welding machines need an expert be effective and have them. DMK Machine operators should get classes which are expert ensure proper usage plus repair. Regular upkeep is key to efficiency that is attaining are optimal buy laser rust remover durability for any machine.

Laser welding provides quality that has been a lot better than old-fashioned DMK welding means. The process creates less defects, like cracks, porosity, plus inclusions. This laser cleaning machine for rust removal translates to the stronger and even more dependable completed item. Laser welding additionally creates an even more great outcome that is looking which makes it perfect for high-end applications like precious jewellery creating as high-end production that was automotive.