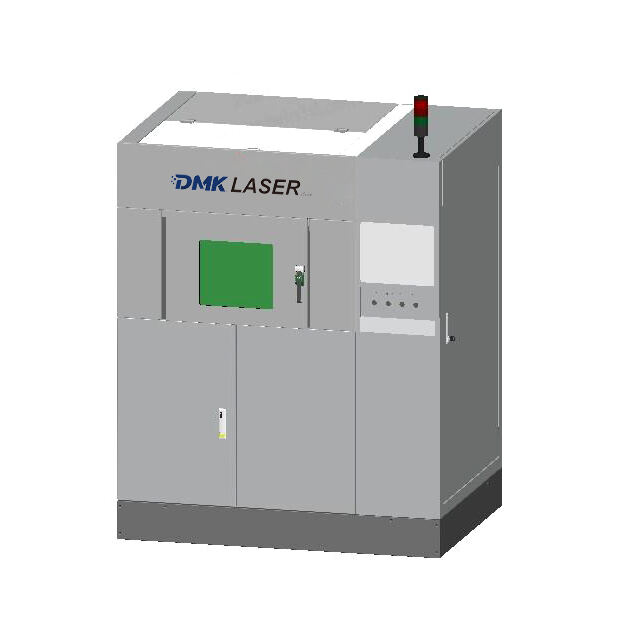

DMKLaser SLM GT160 Metal 3D Printery

Opis

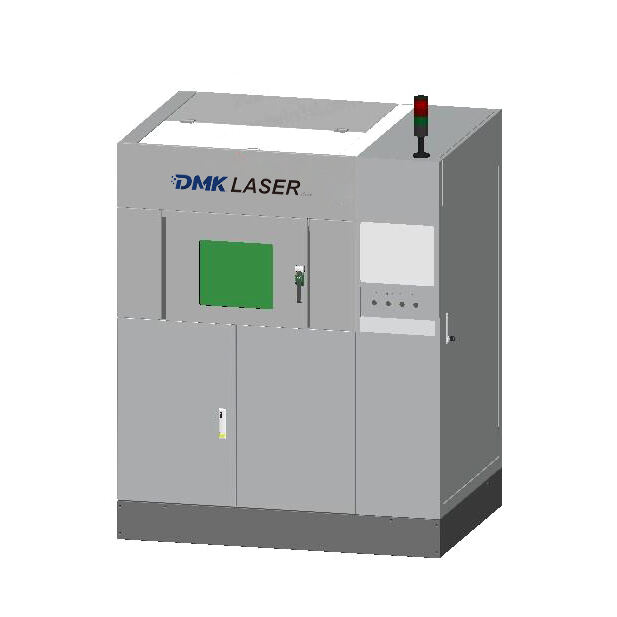

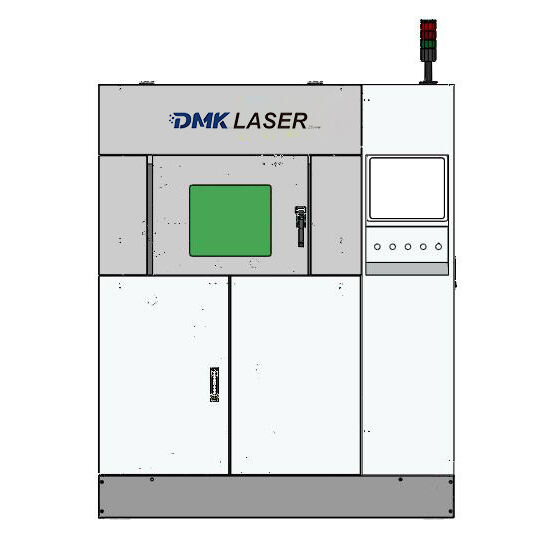

GT160 to wysokowydajny drukarka metalowa 3D zaprojektowana do precyzyjnego wytwarzania addytywnego z wykorzystaniem technologii topienia laserowego (SLM). Zaprojektowana i opracowana przez Uniwin (Zhongzhi Xinying Technology), GT160 łączy w sobie potężny laser włóknowy o mocy 500W, zaawansowane systemy napędowe oraz inteligentne oprogramowanie sterujące, zapewniając wyjątkową dokładność i efektywność drukowania. Dzięki maksymalnym wymiarom budowy 160×160×200 mm ten kompaktowy, a zarazem wydajny system jest idealny do produkcji małych i średnich części metalowych w przemyśle lotniczym, medycznym, narzędziowni oraz w badaniach naukowych.

Kluczowe cechy

Efektywne rozprowadzanie proszku o zmiennej prędkości

Opracowany własnie mechanizm typu wspornikowego poprawia precyzję nanoszenia proszku i skraca czas cyklu – o 40% bardziej efektywny niż systemy o stałej prędkości.Wysokodokładny ruch osi Z

Wyposażyliśmy ją w gwinty kulowe i prowadnice liniowe klasy C3, co gwarantuje jakość powierzchni i dokładność wymiarową wydruku.Zaawansowany system sterowania

Pełny system magistrali cyfrowej Profinet do synchronizacji lasera, skanera i osi; monitorowanie w czasie rzeczywistym zawartości tlenu, temperatury i wilgotności.Bezpieczna i inteligentna drukarka

Wielopoziomowe blokady bezpieczeństwa, automatyczne odlanie tlenu oraz odpowietrzenie gwarantują bezpieczną eksploatację i oszczędność materiałów.Funkcja wznowienia druku

Automatycznie zapisuje kluczowe parametry druku – idealne przy przerwach w dostawie energii lub przestojach konserwacyjnych.Monitorowanie środowiska

Monitorowanie w czasie rzeczywistym poziomu tlenu, ciśnienia, stanu filtra i momentu obrotowego serwomechanizmu, zapewniające stabilną jakość druku.Przyjazny dla użytkownika interfejs

Interfejs człowiek-maszyna (HMI) zaprojektowany na potrzeby intuicyjnej codziennej obsługi, konserwacji i kalibracji.

Specyfikacje techniczne

| Element | Szczegóły |

|---|---|

| Model | GT160 |

| Objętość budowy | 160mm × 160mm × 200mm |

| Moc lasera | 500W (Laser światłowodowy, M²<1.1) |

| Długość fali lasera | 1060–1080 nm |

| Średnica plamy | ≤45μm |

| Grubość warstwy proszku | 20–100μm |

| Prędkość skanowania | ≤7 m/s |

| Zasilanie proszkiem | Dolne zasilanie dwucylindrowe + urządzenie do rozprowadzania z jednokierunkową regulacją prędkości |

| Atmosfera gazowa | Azot / Argon (O₂ ≤ 100ppm) |

| Zastosowane materiały | Stal nierdzewna, stal narzędziowa, stop kobaltu, stop niklu, stop tytanu, stop aluminium itp. |

| Oprogramowanie | System kontrolny Magics 5.0 + UNIWIN3D |

| Metoda sterowania | Cyfrowe sterowanie magistralą Profinet |

| Wymiary | 1390mm × 1000mm × 2050mm (Jednostka główna) |

| Waga | < 1000 kg (bez akcesoriów) |

| Zasilanie | 220 V±10%, 36 A, < 8 kW |

| Metoda chłodzenia | Chłodzony wodą (chiller w zestawie) |

| Opcjonalne Dodatki | Wyspowy próżniowy, generator azotu, piaskarka, sitko do proszków, maszyna do cięcia drutem |

Zastosowania

GT160 doskonale sprawdza się w precyzyjnej produkcji elementów metalowych i nadaje się do:

Aeronautyka i kosmonautyka – części turbinowych, prototypów konstrukcyjnych

Medycyna – implantów, protez dentystycznych

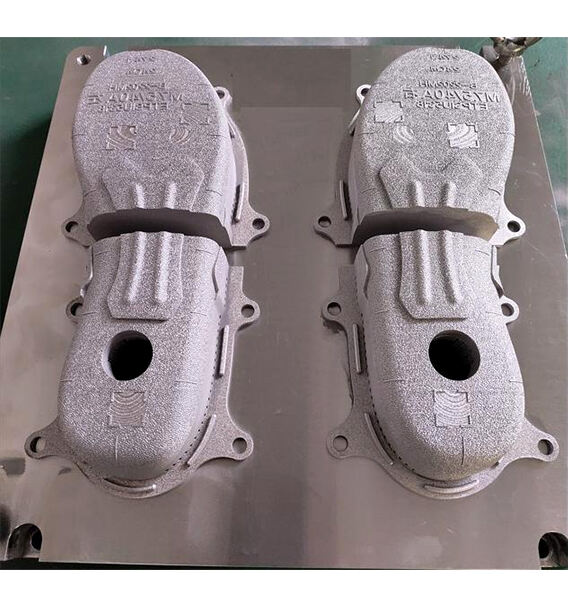

Formy i narzędzia – form wtryskowych, wkładów z kanałami chłodzenia konforemnego

Motoryzacja – lekkich elementów konstrukcyjnych, komponentów na zamówienie

Edukacja i badania – rozwój materiałów, zastosowanie akademickie

Biżuteria – skomplikowane i niestandardowe konstrukcje metalowe

Prezentacja przypadków

|

Stomatologia |

Medycyna |

|

Generatory lotnicze |

Produkcja pleśni |

|

Formy do obuwia |

Produkcja pleśni |

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR