De industriële productie verandert snel doordat nieuwe technologie fabrieken slimmer en sneller maakt. Een belangrijk onderdeel van deze transitie is het gebruik van een fiber laser las systeem. Fiber laser lassen is een methode om metalen samen te voegen met behulp van een intense, geconcentreerde lichtbundel. Het maakt het lasproces ook sneller, schoner en nauwkeuriger. Bij DMK staat fiber laser lassen voor hun "sleutel tot het ontsluiten van het volledige potentieel van moderne productie". Het helpt bedrijven producten beter en sneller te ontwikkelen, wat goed aansluit bij de huidige ontwikkeling naar slimme fabrieken en een nieuwe generatie machines die met elkaar kunnen communiceren. Nu gaan we bespreken hoe fiber laser lassen u een concurrentievoordeel kan geven in de productie en hoe u deze technologie het meest effectief kunt gebruiken

Voordelen van Fiber Laser Lassen in de Moderne Productie-industrie

Laserlassen met fiber zal de manier waarop fabrieken opereren veranderen, waardoor het sneller en betrouwbaarder wordt. Het maakt gebruik van een dunne maar krachtige lichtbundel die metaal precies smelt waar dat gewenst is. Dit betekent dat er minder warmte zich door het metaal verspreidt, zodat onderdelen sterk blijven en niet gemakkelijk vervormen of breken. De lassen zijn schoner en vereisen minder nabewerking na het lassen, omdat de bundel zo nauwkeurig gefocust is. In de auto-industrie bijvoorbeeld, fiber Laser Welding verbindt het snel onderdelen zoals deuren of chassis en houdt deze sterk zonder extra bevestigingen. Bij DMK kunnen wij bijvoorbeeld veel onderdelen in een korte tijd lassen, wat fabrieken in staat stelt om aan de vraag te blijven voldoen — zonder vertraging op te lopen

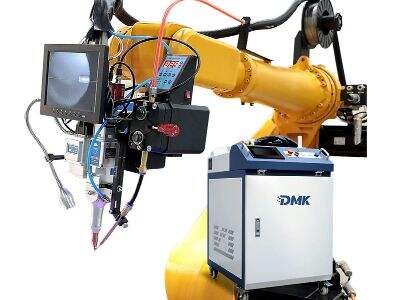

Bovendien kan vezellaserlassen door een computer worden geprogrammeerd, waardoor fabrieken hun werk kunnen automatiseren. Dat betekent dat robots het lassen kunnen uitvoeren met minimale menselijke tussenkomst, wat fouten vermindert en ervoor zorgt dat elke las identiek is. (Robots lassen hun onderdelen met vergelijkbare precisie in een verre fabriek, waar geen werknemers de onderdelen van de mobiele telefoon aanraken.) Minder stilstand, meer productie per dag. Maar er is meer — vezellasers hebben een langere levensduur dan andere lastools en moeten minder vaak worden gerepareerd, dus fabrieken besparen geld en hoeven de productie niet stil te leggen. En vezellaserlassen kan een sterke verbinding behouden op verschillende metalen (van dun plaatwerk tot dikke platen), waardoor het toepasbaar is in diverse sectoren. Deze brede toepasbaarheid stelt bedrijven in staat snel over te schakelen van het ene product op het andere zonder al die apparatuur te hoeven vervangen

Productiekwaliteit optimaliseren met geavanceerde vezellaserlastechnologie

Het halen van optimale efficiëntie uit lassen met een vezellaserapparaat vergt meer dan alleen het aanschaffen van het juiste apparaat. Het is een vak, dat traag instellen vereist. Het soort staal, dichtheid en vorm zijn essentieel om te begrijpen als het gaat om lassen, zoals we onze DMK-klanten voortdurend vertellen. Bijvoorbeeld: het lassen van aluminium vereist andere instellingen dan staal, omdat het op een andere manier smelt en afkoelt. Barsten of zwakkere plekken kunnen ontstaan als er verkeerde instellingen worden gebruikt. Onze expertise wijst uit dat het aanpassen van de energie, snelheid en de grootte van het brandpunt van de laserstraal voor elke toepassing zorgt voor sterke, vloeiende lassen.

Hoge topkwaliteit kan ook gemakkelijk worden verbeterd door slimme sensoren en camera's te gebruiken tijdens het lassen. Deze apparaten houden de las nauwkeurig in de gaten terwijl deze wordt aangebracht en detecteren problemen onmiddellijk. DMK integreert deze intelligente controle in de meeste machines, zodat als er iets niet klopt, de machine stopt en zichzelf corrigeert voordat er defecte onderdelen ontstaan. Deze real-time regeling leidt tot minder verspilling van grondstoffen en oplevert betere eindproducten. Echter, het goed opleiden van medewerkers in het gebruik van vezellaserlassen en de bijbehorende apparatuur is van groot belang. Goede operators kunnen signalen van de machines interpreteren en direct aanpassingen doen tijdens het proces, waardoor de productielijn zonder oplopende fouten blijft draaien.

En tot slot, het onderhouden en schoonmaken van de behuizingen van vezellasers zorgt ervoor dat ze optimaal blijven presteren. Lenzen moeten regelmatig van stof en vuil worden gereinigd, omdat dit het laserstraal kan verzwakken en leiden tot slechte lassen. Bij DMK bieden wij onbelemmerde overzichten en ondersteuning om apparatuur in topconditie te houden. Indien grondig gebruikt en correct begrepen, transformeert vezellaserlassen een goede fabriek tot een uitstekende fabriek. Het gaat dan niet alleen om betere en snellere prestaties, maar ook om het garanderen van de hoge kwaliteit van elk product dat klanten gebruiken, wat hun tevredenheid vergroot en hun vertrouwen versterkt.

Wat is de rol van vezellaserlassen in toekomstige Industry 4.0 supply chains

En Industrie 4.0 is een andere manier van dingen maken — met behulp van slimme machines, computers en internet. Het zorgt ervoor dat fabrieken efficiënter, sneller en veiliger kunnen werken. Vezellaserlassen is een opvallend aspect van deze nieuwe manier. Vezellaserlassen is een specifiek proces dat gebruikmaakt van intense lichtbundels om metalen onderdelen aan elkaar te verbinden. Het is een zeer snelle en nauwkeurige methode en daarom geschikt voor het nieuwe tijdperk van de digitale supply chain van Industrie 4.0. Supply chains zijn de routes waarlangs materialen en goederen van fabriek naar klant bewegen. Binnen vier decennia (afhankelijk van wanneer we besluiten dat deze toekomst is begonnen), lijkt Industrie 4.0, waarin deze supply chains sterker met elkaar verbonden en geautomatiseerd zijn, onvermijdelijk. Vezellaserlasermachines kunnen communiceren met computers en andere slimme apparaten, en werken volledig zelfstandig of met weinig hulp van mensen. Dat is een groot voordeel voor fabrieken, die zo meer producten in minder tijd en met een kleiner risico op fouten kunnen produceren. En vezellaserlassen verbruikt minder energie en verspilt minder dan oudere methoden, wat goed is voor het milieu. De vezellaserlasermachines van DMK zijn ontworpen om naadloos te integreren in slimme fabriekomgevingen. Ze kunnen gegevens over het lasproces verzenden en ontvangen, zodat managers de productie kunnen monitoren en problemen snel kunnen corrigeren. Dit soort real-time datadeling is cruciaal binnen Industrie 4.0, omdat het de gehele supply chain versnelt en de processen betrouwbaarder maakt. Naarmate ze worden bijgewerkt om aan nieuwe klantbehoeften te voldoen, fiber Laser Welding is wat de productie flexibel houdt. Het kan meerdere metalen en vormen lassen, zodat u gemakkelijk tussen producten kunt wisselen. Deze flexibiliteit is zeer belangrijk gezien de snel veranderende eisen van industrie 4.0-toeleveringsketens. Kortom, vezellaserlassen is een essentiële technologie voor industrie 4.0. Het maakt fabrieken slimmer, sneller en schoner. Dankzij de vezellaserlasermachines van DMK kunnen bedrijven het potentieel van slimme productie maximaliseren om superieure producten te maken voor hun klanten

De beste vezellaserlasermachines kiezen voor groothandelsindustriële toepassingen

Het kiezen van het allerbeste vezellaser lasapparaat is eigenlijk essentieel voor productiefaciliteiten, vooral wanneer ze grote hoeveelheden producten snel moeten produceren. Bij de aanschaf van vezellaserlasmachines voor grootschalig commercieel gebruik, zijn hier enkele punten om rekening mee te houden bij het apparaat die kunnen garanderen dat het geschikt is voor de fabriek. Allereerst, overweeg de kracht van de laser. Meer vermogen betekent dat het apparaat dikker staal kan lassen of sneller kan werken. Maar met hoger vermogen komt vaak een hogere prijs en meer energieverbruik. DMK biedt vezellaserlasmachines in verschillende vermogensopties, zodat fabrieken degene kunnen kiezen die het best past bij het type producten dat zij maken. Ten tweede, denk na over de vorm en grootte van het staal dat u gaat lassen. Sommige vezellaserlasapparaten zijn bedoeld voor kleine, precieze klussen; andere zijn ontworpen om grote of onregelmatig gevormde producten te verwerken. Kies een apparaat dat past bij uw materialen en u kunt tijd besparen en de kwaliteit verbeteren. De lassnelheid is ook een belangrijke specificatie. Snellere machines stellen fabrieken in staat om meer producten in kortere tijd af te ronden. Maar snelheid mag niet ten koste gaan van een sterke las. Het vezellaserlasysteem van DMK is de ideale afweging tussen snelheid en precisie om optimale prestaties te leveren. U wilt ook nadenken over hoe gebruiksvriendelijk en onderhoudsvriendelijk het apparaat is. Apparaten die gemakkelijk te bedienen en te repareren zijn, helpen ervoor te zorgen dat de fabriek zonder veel stilstand blijft draaien. Software en onderhoud: de vezellaserlasmachine van DMK is uitgerust met gebruiksvriendelijke software. Tot slot, overweeg hoe goed het apparaat kan communiceren met andere slimme fabriekssystemen. Aangezien Industrie 4.0 draait om apparaten die met elkaar communiceren, is een vezellaserlasapparaat dat gegevens kan verzenden en op afstand kan worden bediend een krachtig voordeel. Deze slimme functies worden mogelijk gemaakt door het apparaat van DMK dat naadloos integreert in de huidige fabrieksomgevingen. Als deze bedrijven hun vezellaserlasapparaten kiezen met het juiste vermogen, de juiste afmetingen, snelheid, gebruiksgemak en slimme functies in gedachten, kunnen groothandels hun efficiëntie optimaliseren en concurrerend blijven. DMK biedt vezellaserlasmachines met al deze functies, zodat bedrijven kunnen groeien in de steeds veranderende wereld van Industrie 4.0

Wat zijn de populaire kenmerken van vezellaserlassen die de productie in groothandel verhogen

De vezellaserlasertechnologie blijft zich ontwikkelen en verbeteren, zodat fabrieken sneller betere producten kunnen produceren. Hieronder volgen enkele structurele kenmerken die momenteel populair zijn fiber Laser Welding machine voor groothandel, die productiviteit aanzienlijk kan verbeteren. Een opkomende trend is eigenlijk automatisering. Laservoeglasapparaten kunnen gemakkelijk zelfstandig draaien of zelfs met zeer weinig menselijke ondersteuning. Dat vermindert fouten en verlaagt productiekosten. De vezellaser lasertoestellen bij DMK worden allemaal aangeboden met automatisering, wat productiefaciliteiten in staat stelt 24/7 te opereren, het verhogen van output zonder arbeidskosten te verhogen. Real-time volgen is nog een van de uitstekende functies. Dat betekent dat het apparaat gegevens verzamelt over het lastoestel en deze onmiddellijk kan verzenden naar leidinggevenden. Als er iets misgaat, kan het worden opgelost voordat het een groot probleem wordt. Maar als wij real-time kunnen bewaken, kunnen wij hoge kwaliteit garanderen en verspilling verminderen. DMK-apparaten zijn uitgerust met hoogwaardige sensoren die deze cruciale gegevens produceren. Nauwkeurigheid en controle als trends worden steeds prominenter. Nieuwe vezellaser lasertoestellen zijn in staat om deze specificaties nauwkeurig aan te passen via de energie, snelheid en focuscapaciteit van een pomp. Met deze controle kunnen sterke en schone lassen ook worden bereikt in dunne of complexe onderdelen. Hoe beter de las, hoe minder productfouten en hoe minder herstellingen — wat tijd en geld bespaart. Bij DMK Precision Machining is DMK toegewijd aan precisiebewerkte onderdelen voor diverse productiebehoeften. Enkele andere functies die wij waarderen: gebruiksvriendelijke interfaces. Intuïtieve touchscreens en eenvoudige software stellen operators in staat om snel lastoestellen in te stellen en te bedienen. Het is gemakkelijker om nieuwe werknemers op te leiden, en er worden minder fouten gemaakt. De service van DMK ontwikkelt apparaten met gebruiksvriendelijke bedieningen, waardoor het mogelijk is voor operators om met vertrouwen te werken. Tot slot is connectiviteit een belangrijke trend. Vezellaser lasertoestellen die koppelen met andere slimme apparaten en fabriekssystemen, ondersteunen een vlotte, efficiënte productiestroom langs de productielijn. Deze koppeling ondersteunt Industrie 4.0-doelstellingen, door gegevensdeling en afstandsbediening mogelijk te maken

Inhoudsopgave

- Voordelen van Fiber Laser Lassen in de Moderne Productie-industrie

- Productiekwaliteit optimaliseren met geavanceerde vezellaserlastechnologie

- Wat is de rol van vezellaserlassen in toekomstige Industry 4.0 supply chains

- De beste vezellaserlasermachines kiezen voor groothandelsindustriële toepassingen

- Wat zijn de populaire kenmerken van vezellaserlassen die de productie in groothandel verhogen

EN

EN

AR

AR CS

CS NL

NL FR

FR DE

DE IT

IT JA

JA KO

KO PL

PL PT

PT RU

RU ES

ES UK

UK TH

TH TR

TR