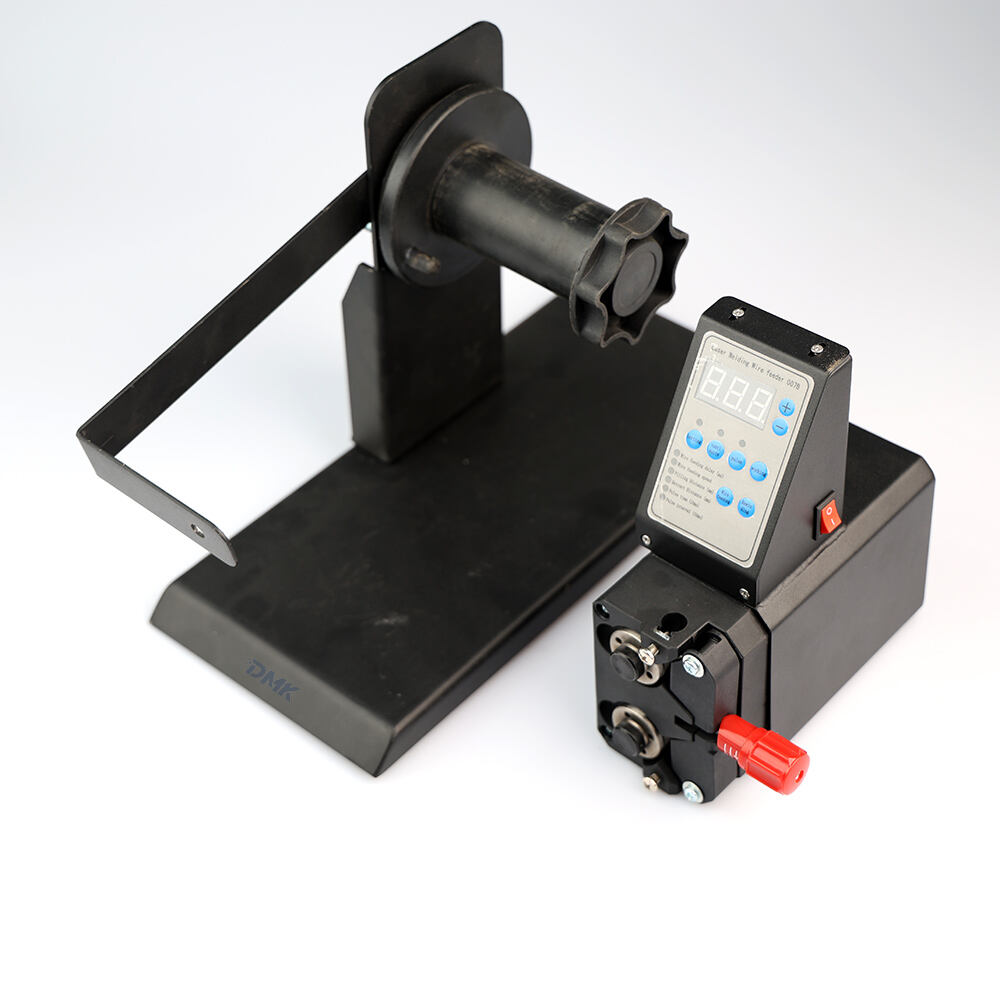

When designing beautiful jewelry you must be cautious. Every little thing you do can make a difference, and one minute error can ruin the entire project. This is why the laser solder machine of DMK is used in the jewel-making field when it comes the time to benefit from this special welding technology.

With DMK's state-of-the-art solder machine, jewelers can solder precisely and finely, down to the smallest and most complex design—perfect every time. The laser enables them to get a strong connection, which means they don’t have to worry about the edges coming up, or there being part of a piece being slightly higher than another.

1) Making good work is a BIG priority, and every jeweler wants to make pieces that are not only pretty but that are also made well. DMK's laser solder machine will help your jewelry be better, and help you be better at the craft.

You can make detailed specific designs with the machine due to its precision. **** Whether you are working on small earrings or a large necklace, you can rely on you solders to be strong and look great. This level of attention to detail is going to go a long way with your customers and help you stand apart from other jewelers.

Soldering is an important process when crafting a piece of jewelry because it joins separate pieces together. But there are several problems with traditional soldering — it can be messy, and it’s not very precise, which can result in weak connections. With DMK's laser soldering machine, you can have perfect results again and again.

The use of laser technology processes every solder joint to be precipitate, strong and uniform. This equates to better looking jewelry that will keep looking beautiful and last for years to come. By spending less time on cleaning up messy solder, you can spend time on making beautiful pieces your customers will love.

Creating jewelry is an art that requires skill, patience, and creativity. In my line of business as a jeweler, you never stop wanting to do better or make something no one else has. Create jewelry that works better with DMK's new laser solder machine and reach new heights in design.

We always adhere to the core values of "customer-centricity" and "creating customer-satisfying benefits." We put client service first on our concern list. We actively participate in the "Made in China 2025 initiative" making use of tools and services that assist modernize the jewelry laser solder machine effectively. Our company is afflicted with the dual forces Internet+ and Industry 4.0 to adapt ourselves to the needs of the internet era that are industrial. You are able to expect the fundamental laser that are advanced technology in addition to application service that one may find along with work with our partners to attain greater speeds, more economical and quicker development.

DMK try situated in the East Lake High-Tech Development Zone (Optics Valley) positioned in Wuhan, China. Our company is a company that are highly-tech are expert in research, development, and manufacturing of complete sets of laser equipment. We now have a few dozen postgraduates and researchers in our creator's team. With our contemporary manufacturing center for laser equipment, along with a skilled staff that is after-sales can afford to provide custom solutions for jewelry laser solder machine processing equipment to domestic and worldwide users. We offer the professional service which was after-sales resolve any product-related problems quickly.

We have included the absolute most laser that is up-to-date into our processes. We work with jewelry laser solder machine which is domestic and control system providers like Raycus MAX, JPT Friendess Raytools SUP QILIN ESTUN. We find the elements which can be best our laser equipment, control assembly procedures, and conduct rigorous inspections regarding the factory. As a result, help us enable Chinese production to enhance the everyday lives constantly of most of our users round the world.

Our company possesses an offer that was considerable which comprises 8 biggest types of products and the selection which is big of, such because complete machines for laser cutting, laser welding, and laser cleansing. We furthermore have actually equipment like fiber lasers and laser minds. Our things are widely used in industries like sheet metal processing because well since equipment for ecological protection. Additionally, they find use in the industries of {keyword}, shipbuilding’s and aerospace, together with new shipbuilding and power. Our products, which may import and export independently and are growing in the share of this marketplace internationally in regions like East Asia, North America and Latin America, Middle East, Western Europe and Russia.