اللحام بالليزر ذو التغذية السلكية هو طريقة رائعة لربط المعادن وهو يتضمن جهازًا خاصًا يسمى مسدس إزالة الصدأ بالليزر . هذا الجهاز لديه القدرة على جعل اللحام أسرع وأكثر دقة. اليوم سنكتشف عن اللحام بالليزر ذو التغذية السلكية - ما هو وكيف يعمل!

اللحام الليزري باستخدام السلك يتم عن طريق الشعاع الليزري، والذي يذيب الأجزاء المعدنية ويدمجها معًا ككتلة واحدة. تعرفين/تستخدم نوعًا من المشع الباهر جدًا الذي يذيب قطعتين معدنيتين ويجعلهما تتصلان معًا! كما أن الجهاز يستخدم سلكًا رفيعًا يدخل في شعاع الليزر لملء الفجوات بين قطع المعدن. وهذا يجعل اللحام أقوى.

متى يجب استخدام جهاز اللحام بالليزر مع تغذية السلك هناك العديد من الطرق التي يمكن أن يكون فيها جهاز إزالة الصدأ مفيدًا. أحد الأسباب الكبيرة هو القدرة على لحام قطع معدنية رقيقة جدًا دون تشوهها. لذلك فهو مفيد للأمور مثل الإلكترونيات والمجوهرات حيث تكون الدقة مهمة. كما أنهم يعملون بسرعة كبيرة ويساعدون الشركات على توفير الوقت والمال. وهم ينتجون حرارة أقل من تقنيات اللحام الأخرى، لذا فإن المعدن يظل غير محترق.

جهاز لحام بالليزر مع تغذية سلك – يبدو صعبًا؟ ليس كما تعتقد... اللحام باستخدام جهاز لحام الليزر مع تغذية السلك قد يبدو صعبًا عند المحاولة الأولى، ولكنه يتحسن مع الوقت. أولاً، تأكد من أن الجهاز مُعد بشكل صحيح وأن شعاع الليزر مركّز بشكل دقيق. عليك أيضًا إدخال السلك في مسار شعاع الليزر بشكل صحيح وبسرعة واتجاه مناسبين للحصول على لحام قوي. من الجيد التدرب على بعض المعادن الخردة قبل البدء بالقطعة النهائية.

يستخدم العديد من الأشخاص في الصناعات المختلفة اللحام بالليزر مع تغذية السلك. في صناعة السيارات، يستخدم لحام الأجزاء المعاً، بما في ذلك أنظمة العادم. وفي صناعة الطائرات، فإنه يساعد على الحفاظ على خفة وزن أجزاء الطائرة مع تعزيز قوتها. أما في المجال الطبي، فيمكن أن يساهم في تصنيع أجهزة طبية موثوقة. بغض النظر عن الصناعة، فإن عملية اللحام بالليزر مع تغذية السلك دائمًا ما تجعل المنتجات أفضل.

كما هو الحال مع جميع الآلات، تحتاج ماكينات اللحام بالليزر ذات التغذية السلكية إلى صيانة للعمل بكفاءتها القصوى. وهذا يشمل التنظيف occasional والتحقق من وإصلاح أي شيء قد يكون مترهلًا، وضمان أن جميع الأجزاء في حالة جيدة. إذا ارتكبت خطأ - لا يركز شعاع الليزر بشكل صحيح، أو لا يتم تغذية السلك - لا تقلق. الرجوع إلى دليل الجهاز للحصول على المساعدة أو استشارة محترف.

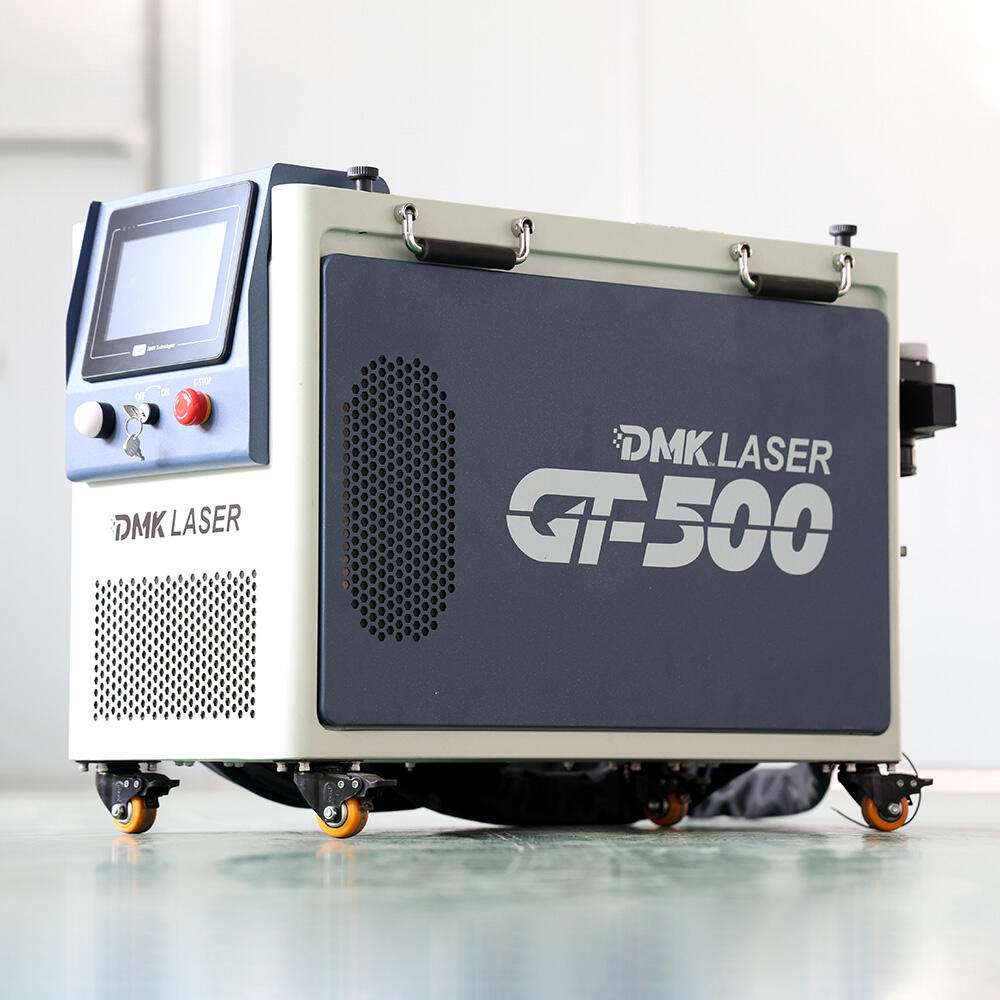

شركتنا تأتي بعرض شامل يشمل ثمانية أنواع رئيسية من المنتجات وتنوع كبير، مثل المعدات الكاملة التي يمكن استخدامها لقطع الليزر، {الكلمة الرئيسية}، وتنظيف الليزر، بالإضافة إلى معدات مثل ليزر الألياف ورؤوس الليزر. يتم استخدام منتجاتنا عادةً في الصناعات مثل معالجة المعادن الصلبة وأجهزة الحماية البيئية والآلات الزراعية وتطوير الطاقة الجديدة. يمكن لمنتجاتنا تصدير واستيراد نفسها وتزداد حصة أسواقها في المناطق العالمية بما في ذلك شرق آسيا، أمريكا الشمالية، أمريكا اللاتينية، الشرق الأوسط، أوروبا الغربية وروسيا.

نحن نتمسك باستمرار بالقيم الجوهرية المتمثلة في «التركيز على العميل» و«خلق قيمة ترضي العملاء». ونعتبر احتياجات العملاء الشاغل الرئيسي الذي يُحدِّد أولوياتنا. ونشارك بصدق في مبادرة «صنع في الصين ٢٠٢٥»، ونستعين بالتكنولوجيا والخدمات لدعم تطوير أسواق الليزر بطريقة ذكية. ونتعامل مع متطلبات العصر الصناعي القائم على الإنترنت من خلال قوتين رئيسيتين هما: مفهوم «إنترنت+» و«الثورة الصناعية الرابعة (Industry 4.0)». ونوفر جهاز لحام الليزر بتغذية الأسلاك (wire feed laser welder) الضروري حسب نوع التطبيق المطلوب، إضافةً إلى تقديم خدمة تطبيقية شاملة، كما نتعاون مع شركائنا لتحقيق كفاءة أعلى، وتطوير أسرع وأكثر فعالية.

توجد شركة DMK داخل منطقة ووهان للتنمية التكنولوجية العالية الواقعة ببحيرة دونغ. ونحن مؤسسة متخصصة في مجال التحليل والتطوير والتصنيع الشامل لمعدات لحام الليزر التي تُغذَّى بالأسلاك. ويضم فريق مبتكري شركتنا عدداً كبيراً من العلماء والخريجين الحاصلين على درجات عليا. ولدينا حالياً مرافق إنتاج متطورة جداً لمعدات الليزر، إضافةً إلى فريق من المتخصصين في خدمات ما بعد البيع، قادرين على تقديم حلولٍ مُخصصة للعملاء في الأسواق الدولية والداخلية على حدٍ سواء. كما نقدّم كذلك دعماً خبيراً ما بعد البيع لمساعدة العملاء في حل أية مشكلات تتعلق بالمنتج بشكلٍ فوري.

لقد أدرجنا في عملياتنا أحدث أنظمة الليزر المتوفرة حاليًّا. ونعمل باستخدام آلة لحام ليزرية تعمل بتغذية الأسلاك، ومورِّدي أنظمة التحكم المحلية مثل Raycus وMAX وJPT وFriendess وRaytools وSUP وQILIN وESTUN. ونحرص على اختيار العناصر التي تتناسب أفضل ما يمكن مع معدات الليزر الخاصة بنا، وإجراءات تجميع الأنظمة، وإجراء فحوصات صارمة في المصنع. ونتيجةً لذلك، يُمكِّننا الإنتاج الصيني من تحسين جودة الحياة اليومية باستمرار لمعظم مستخدمينا حول العالم.